Busbars vs. Cables

Why busbars are better than cables:

Busbars have a higher current carrying capacity

Despite having the same cross-section, cables have a smaller surface area than rectangular busbars due to their round shape. Cables therefore have a lower heat dissipation and also a lower current carrying capacity. If busbars are used instead of cables, a smaller cross-section can therefore be selected.

In short: larger surface area = higher current carrying capacity.

In addition, the larger surface area of busbars compared to cables ensures that the current flow is better distributed and the so-called skin effect is reduced. The efficiency of the power transmission is improved.

Busbars offer flexibility

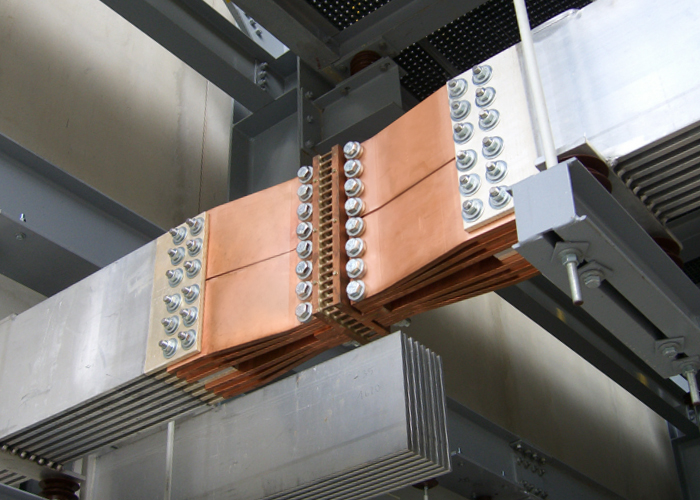

Installing busbars is easier than with cable systems thanks to fewer mounting points. They are used for power distribution in, for example, generators, transformers, switchgears, as a supply line to machine switches and immersion baths or as a riser in switchgears. Whether as flexible components, assembly units or as massive busbar systems, our busbars are innovative electrical connections.

Busbars have the better operational reliability

Particularly with busbar systems, parallel installation with bars always results in the same conductor lengths. With cable systems, on the other hand, different lengths with different loads can result depending on how they are installed. Busbars therefore have a high level of operational safety and a low fire load. We will be happy to advise you.

Busbars save working time

The use of busbars not only saves time in the planning, but also in the installation and execution of the power distribution. A small busbar can be mounted at two points, while a cable requires much more work in terms of cutting to length and crimping.

Busbars can be extended as required

Thanks to their modular design, busbars are extremely flexible and can be expanded almost infinitely. Installing busbars does not usually require any complex laying work, as is the case with conventional cables. This makes busbars the ideal solution in many areas, from electrical engineering to solar technology.

Busbars are recyclable

Metals such as aluminum and copper are valuable raw materials.

Copper is one of the metals that is easiest to recycle, as it does not lose any of its quality during the recycling process. It can be melted down and reused as often as you like without any impairment to its properties.

Recycling busbars not only makes economic sense and helps to save energy, but also helps to conserve natural resources. Contact us and we will give you sustainable advice.

Your project progress with EMS solutions

Contact & Offer

In an initial conversation – online or on site – the first framework conditions are clarified, and possible solutions are discussed.

Our motivated EMS sales team ensures that the results meet your needs, from the initial consultation to the final offer.

Use our various contact options and get advice on your project. After consultation, you will receive an individual offer tailored to your problem.

Planning & Development

We work closely with you to engineer projects systematically and implement them efficiently. In doing so, we focus on optimizing functionality as well as infrastructural, production-related and economic aspects. The result is customized solutions that are geared towards profitability and meet customer requirements down to the last detail.

We also provide support in preparing tenders and specifications.

Engineering & Design

Our experienced engineering experts and designers, as well as the latest technologies, guarantee needs-based results in analysis, calculation, simulation, testing technology and prototype construction.

Among other things, this involves defining the busbar routing and determining the current-carrying capacity and busbar material. When selecting the busbars, you should be guided by the requirements of the current load, the environment, and the type of equipment to be connected to the busbars.

Manufacturing

Our well-rehearsed manufacturing team works in multiple shifts to ensure that we can react flexibly and manufacture your components and assemblies to the desired quality. We are also able to manufacture individual pieces, prototypes, small quantities, but also large busbars with expansive dimensions and in high quantities while maintaining the highest quality.

No matter how individual your requirements are, EMS has the right solution and is equipped for your order.

Logistics

EMS has high-quality, needs-based packaging – according to your specifications if you wish. This is why we are able to quickly and flexibly put together your orders into new shipping units according to your specifications. This is how we ensure that unnecessary waiting times are minimized and capacities can be dynamically adjusted.

We also coordinate production-related services for you, such as material procurement and component management, as well as post-production and pre-transport activities, such as labeling and packaging of the components and system solutions you have ordered.

Assembly

Our portfolio ranges from simple component manufacturing to fully pre-assembled assemblies. These also include complete switching components for circuit breakers from 1000 A to 6300 A, as well as complex solutions, such as for the wind industry and e-mobility. The entire development process is characterized by direct and intensive exchange with our customers. In doing so, we ensure that all components meet the defined quality requirements. If required, in addition to development and manufacturing, we also take on component assembly ex works or on site.

Commissioning

Before commissioning, the entire installation, including the connections, must be carefully checked for faults or damage. All work steps are documented to ensure traceability and to eliminate possible problems at a later date.

Aftersales

We are there for you even after the project is completed. Thanks to our retrofit expertise, subsequent modernization or adaptation of existing systems is possible at any time.

To do this, we will take a thorough inventory of the old busbar system for you and analyze the condition of the existing lines, insulators, connections, and fixings. To ensure reliable and safe power transmission, we make sure that the renewed system is properly grounded to meet safety standards. This includes resistance measurements, insulation tests and load tests.

Our service

Consulting

+ Individual offer

+ Detailed measurement

+ Guarantees

+ Contract conditions

+ Cost optimization

+ PPAP production release procedure

+ APQP guidelines

+ Audits

Engineering

+ Project management

+ Technical engineering

+ Cross-section design

+ Magnetic field calculation

+ 3D layout creation

+ Feasibility check

Customized manufacturing

+ Fabrication & Manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assemblies

+ Further processing

+ Personalizations

Logistics

+ Worldwide shipping

+ High quality packing

+ Upon request according to specification

+ Reliable & just-in-time

+ Dynamic capacity adjustment

Installation

+ Pre-assembly ex works

+ On-site installation

+ Supervision

After Sales

+ Maintenance

+ Spare parts requirement

+ Retro-fit

Flexible or solid

FAQs about our Busbars

Busbars or conductor rails are used, among other things, as electrical conductors in high-current engineering, high-voltage engineering, the electrical industry, the chemical industry, power supply, regenerative energies, storage technology, mechanical engineering and the e-mobility.

In order to achieve the lowest possible voltage drop, we use only highly conductive pure copper Cu-ETP (E-Cu) or OF-Cu for your copper busbars. In addition, copper busbars can be electroplated very well, which is why they are often used in electrical engineering for shunts or similar applications.

Aluminum busbars are also used as conductors for optimized heat transfer at contact surfaces. Under certain environmental conditions, pure aluminum forms a closed aluminum oxide layer (Al2O3). This property makes aluminum highly resistant to corrosion from external influences.

CoppAl® is a bi-metal composite used as an electrical connection in control cabinets, switchgear and distribution boards. CoppAl® bars are more cost-effective than copper busbars with the same current-carrying capacity.

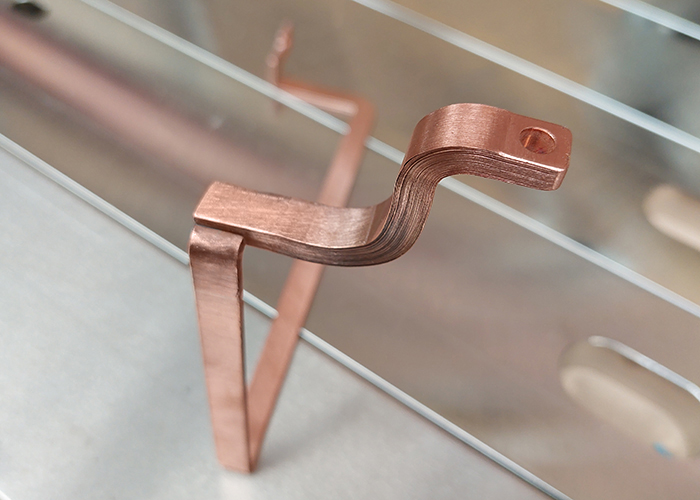

Flexible busbars are electrical conductors that provide individual connection options for safe current flow. Our flexible busbars are made of highly conductive materials such as copper lamellae or Braided Flexible Busbars and are available in customer-specific cross-sections. In contrast to solid busbars, flexible busbars can be installed even in confined spaces and at angles, making them a space-saving and reliable solution for power distribution in industrial applications. They also offer increased safety as they are generally resistant to wear, abrasion and fire.

Flexible busbars offer greater flexibility and are easier to install than fixed busbars.

They can also be better adapted to their surroundings and require less installation space. Furthermore, they are often lighter and cheaper than solid busbar systems. Flexible busbars are usually attached to machines, devices, or walls using clamps or screws. They can be mounted in straight or curved forms as needed.

Our laminated copper busbar Isoflexx® can be used for all electrical connections in low-voltage systems. The loose copper lamellae in the insulation offer excellent flexibility and are also suitable for drilling or punching.

Our laminated expansion busbars with pressure-welded connections have low contact resistance and are easy to install. Expansion Busbars prevent damage to device connections during switching shocks, for example.

There are indeed flexible busbars that are suitable for high currents. However, it is important that the busbars meet the requirements of the electrical installation and that the maximum current is not exceeded. We will be happy to advise you.

U-shaped busbars provide continuous and reliable connections. The reason for this is that the U-shape has a better weight distribution, which avoids deformation due to excessive forces.

They are easy to extend, reconfigure or reposition, and they apply constant pressure to each connection.

U-shaped busbars provide a solid connection and require no routine maintenance.

To increase energy efficiency and manage demand fluctuations, busbar systems are often the solution. They not only reduce system costs and improve reliability, they also increase capacity and help to avoid wiring errors. The physical structure of a busbar is an advantage because it offers unique mechanical design features. For example, busbar consisting of multiple layers provides better structural integrity than other wiring methods.

Some busbar offers the option of current monitoring as a stand-alone system that can be panel mounted or integrated into busbar and feeder circuit applications. We would be happy to advise you.

Busbars are made of corrosion-resistant copper, Cuponal or Aluminum. Although copper oxidizes over time, its conductivity remains, but more energy is needed to conduct the current over the surface. Therefore, three main purposes for the coating of busbars are usually pursued:

- prevention of corrosion

- increasing conductivity

- for optical purposes

Our coating and insulation options can be found here: https://ems-power.com/en/plating

Flexible Customized Busbars

Whether you need flexible busbars made of highly conductive Cu-ETP1 copper mesh or lamellar components, we manufacture everything from simple components to fully pre-assembled assemblies individually according to customer requirements.