Customized & highly flexible Ultraflexx

- Very good flexibility

- Material & space saving

- High quality

- Customized manufacturing

Ultraflexx® busbars are ideally suited for flexible use of space and are the best alternative to prefabricated cables. Thanks to our different cross-sections, Ultraflexx® busbars can be adapted to a wide range of equipment and used as connectors between various control cabinet modules and units.

We manufacture customized highly flexible Ultraflexx® busbars for your system solutions – contact us!

Highly flexible busbars - Conductor Material & Connections

Braided conductor material

Ultraflexx® highly flexible busbars are made of flat copper braid and reliably absorb vibrations and switching shocks.

- Highly flexible flat fabric made of Cu-ETP1

- Single wire diameter 0.15 mm

- Electrical conductance 58 MS/m

SPS Standard Produkte Schwanenmühle GmbH offers standard Ultraflexx® from stock. Please visit our SPS website or our SPS online store!

Ultraflexx® connections

The press-welded connections are (contrary to the generally available press technology) press-welded over the entire connection cross-section:

- The connection ends can be machined like a solid end piece

- They are vibration-resistant and allow the lowest contact resistances to pass through

- Lower power dissipation and smaller voltage drop

- No corrosion and thus no deterioration of the terminal resistances over time

The EMS Group is certified according to

DIN EN ISO 9001:2015

Insulation properties of the highly flexible busbars

Resistant insulated and highly flexible

Ultraflexx® highly flexible busbars are resistant insulated to withstand high operating voltages:

- Halogen-free polyolefin tubing, black

- Wall thickness 0.8 ±0.3 mm

- Operating temperatures -55° C to +125° C

- Flame retardant according to UL 224 – VW 1

- Operating voltage max. 1000 VAC – 1500 VDC

- Dielectric strength 20kV/mm

Approval of Standard-Ultraflexx® from SPS

UL 508

Standards

CE, REACH, ICE 61439-1

Ultraflexx® current carrying capacities

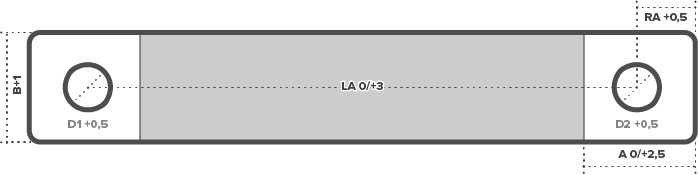

ULFX [cross section mm²] –

[LA = hole spacing length] –

[D1 / D2 = hole diameter]

Lengths [LA] from 150-1000 mm in 50 mm steps. The length is defined as hole center distance.

For Ultraflexx® highly flexible busbars, the current carrying capacity is determined according to the following table based on IEC or UL standards:

Individual Ultraflexx® busbars on request at any time!Anfrage!

| Typenbez. / Type | Querschnitt / Cross section [mm²] | LA Länge / Length [mm] | D1/D2 Durchmesser / Diameter [mm] | A Anschlusslänge / Length connection [mm] | B Breite / Width [mm] (± 1) | RA Abstand / Distance [mm] | Gewicht / Weight [kg/m] | Dicke Innen : Anschluss / Thickness inside : connection [mm] | Leitertemp. /Conductor temp.[A]* 65 °C | Leitertemp./ Conductor temp. [A]* 85 °C | Leitertemp./ Conductor temp. [A]* 105 °C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ULFX 25-LA-D1/D2 | 25 | 150-1000 | 8,5/10,5 | 35 | 20 | 9 | 0,25 | ca. 1,5 : 1,4 | 159 | 210 | 250 |

| ULFX 50-LA-D1/D2 | 50 | 150-1000 | 8,5/10,5 | 35 | 20 | 9 | 0,51 | ca. 3,9 : 2,8 | 236 | 311 | 370 |

| ULFX 100-LA-D1/D2 | 100 | 150-1000 | 10,5/10,5 | 35 | 20 | 9 | 1,02 | ca. 8,0 : 5,9 | 350 | 462 | 550 |

| ULFX 120-LA-D1/D2 | 120 | 150-1000 | 10,5/10,5 | 35 | 32 | 12 | 1,22 | ca. 4,6 : 4,4 | 382 | 504 | 600 |

| ULFX 240-LA-D1/D2 | 240 | 150-1000 | 10,5/10,5 | 35 | 32 | 12 | 2,44 | ca. 9,1 : 8,9 | 688 | 908 | 1.080 |

| Leitertemp. /Conductor temp.[A]* 65 °C | Leitertemp./ Conductor temp. [A]* 85 °C | Leitertemp./ Conductor temp. [A]* 105 °C |

* Current load values: ambient temperature 35 °C, AC current AC. Please use a multiplication factor of 1.72 when using 2 Ultraflexx® and a multiplication factor of 2.25 when using 3 Ultraflexx® in parallel arrangement.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit