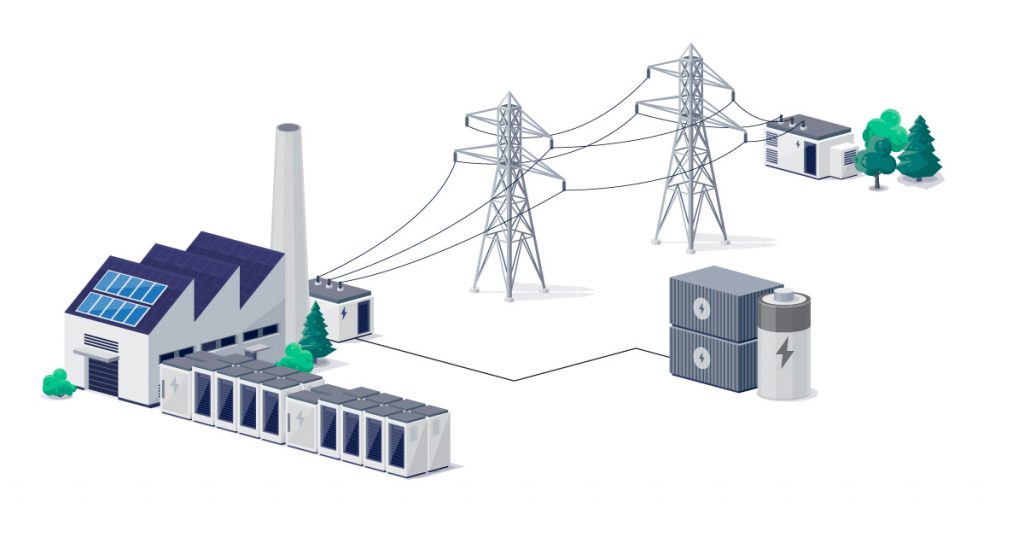

System solutions for switchgear

Flexible and solid busbars made of copper, aluminum or CoppAl® serve as the central distribution board in your switchgear.

With our know-how and individual components, we always engineer your system solutions to measure and according to your specifications.

Whether for switchgear, control cabinets or other applications – we will be happy to advise you!

For all electrical connections in your switchgear

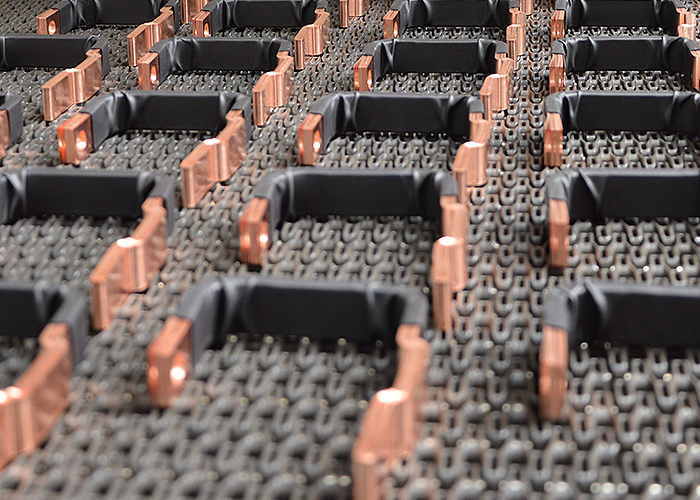

Highly flexible busbars

Highly flexible busbars such as our Ultraflexx® busbars, are made of flat copper mesh and reliably absorb vibrations and switching shocks.

Ultraflexx® are ideal for flexible use of space and are the best alternative to prefabricated cables. Thanks to our different cross-sections, Ultraflexx® busbars can be adapted to a wide range of equipment and used as connectors between various control cabinet modules and units.

Flexible busbars

Flexible busbars such as our Isoflexx® can be used for all electrical connections in control cabinets and systems in the low-voltage range.

Whether as a moving component within solid busbar systems, for connection to generators, transformers, switchgear and switching devices, as a supply line to machine switches and immersion baths, or as a riser in switchgear – Isoflexx® busbars are innovative and reliable connections.

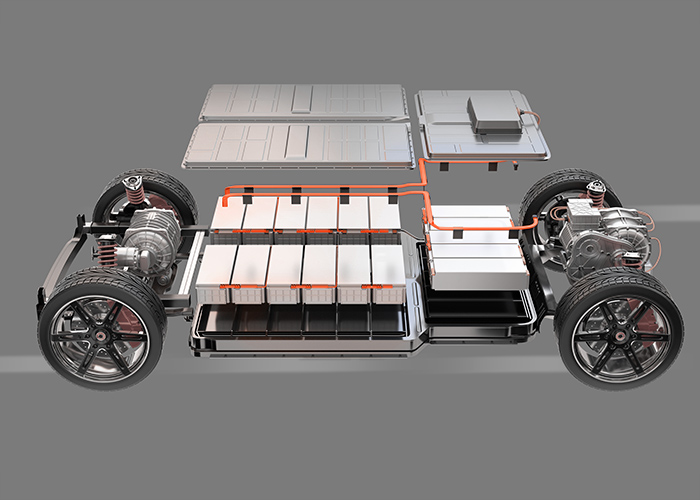

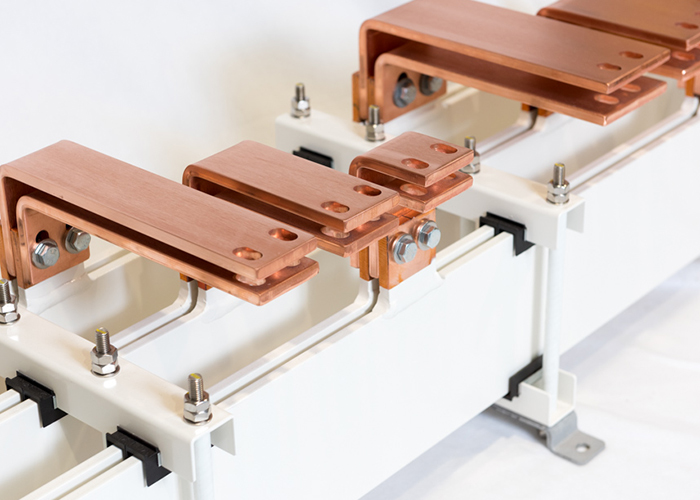

Solid busbars

Solid busbars are used as central distributors in switchgear. In order to achieve the lowest possible voltage drop or transport loss, conductive materials such as copper or aluminum are used for busbars. EMS also offers CoppAl®, a composite busbar with an aluminum core and copper cladding.

With the same cross-sectional area, copper offers the best current strength and thus also current density compared to CoppAl® and aluminum. If the smallest possible cross-section is required, copper is therefore the best choice. If, on the other hand, a low weight is desired, aluminum is the best material.

Wir entwickeln Ihre Baugruppen

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

4 reasons why busbars are better than cables!

At EMS, we have many years of experience in engineering, manufacturing and installing innovative busbars for your switchgear.

Higher current carrying capacity

Compared to busbars, cables have a smaller surface area and thus lower heat dissipation. Thus, a cross-section reduction compared to cables is possible due to optimal geometry.

Installation convenience

The installation of busbars is easier than with cable systems due to standard lengths and few fastening points. In addition, there is no waste. This results in a simpler calculation with less risk.

Short-circuit resistance

Particularly in the case of busbar systems, parallel routing with busbars always results in the same conductor lengths; in the case of cable systems, on the other hand, different lengths with different loads can result depending on the routing. In addition, busbars have high safety in operation and a low fire load.

Time saving

Busbars save time - with busbars you not only save time during planning, but also during installation and execution of power distribution.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

online-Meeting

Book your consultation appointment now:

Florian Müller

P: +49 6307 9116-178

M: +49 162 2036725

E: fmueller@ems-power.com

You would like to receive an offer directly? Then simply use our form - we look forward to hearing from you!

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.