Technically well-engineered system solutions

EMS stands for holistic performance – solving complex tasks is therefore one of our core competencies. In close cooperation with you, we engineer projects systematically and implement them efficiently. The optimization of functionality is just as important as infrastructural, production and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

In addition to our in-house manufactured components and solutions, we also offer our OEM customers customized support for all stages of the manufacturing process. If required, we can already assist you in the development and conception of prototypes and accompany you from the technical design and calculation right through to series production. Experienced engineering experts and designers, as well as state-of-the-art technologies, guarantee 100 percent needs-based results in analysis, calculation, simulation, test engineering and prototype production. Feel free to contact us – we are ready to take on any challenge.

Engineering according to customer requirements

Engineering for integrated system solutions

- Design & layout creation

- Design of cross-sections

- Optimal selection of materials & manufacturing methods

- Simulations

Our experienced EMS designers will find a right solution for almost any application.

Consulting & Services

- Project Management

- Technical development & consulting in high-current technology

- Preparation of tenders and specifications

Our motivated EMS team guarantees result-oriented solutions, from consultation to quotation.

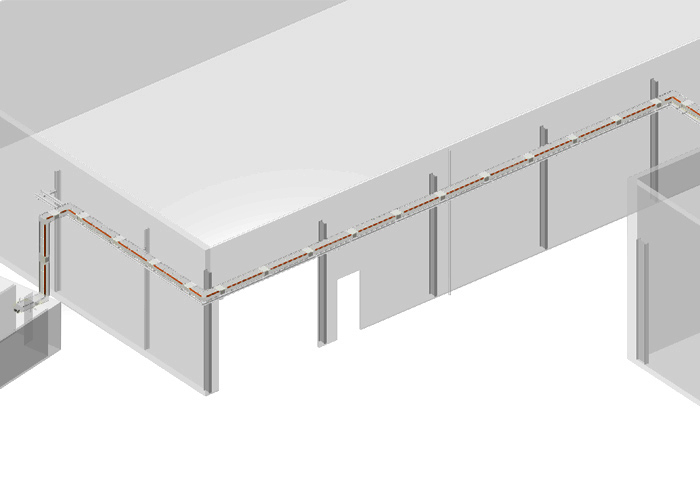

3D Busbars as Digital Twins

- Engineering of precise 3D models

- Integration into BIM systems

We have an experienced engineering department that is able to provide exact 3D models and thus a digital twin of your busbars. We have recently started offering this service for the engineering of the Vision®Bar busbar system as well. These models can be easily integrated into a BIM (Building Information Model) system by our customers.

Digital twins have the potential to fundamentally change the way you think about power transmission – talk to us!

Test Fields for System Solutions

- Temperature & short circuit calculation

- Mechanical & electrical detailed design

- Heating test up to 10 kA

We carry out tests in accordance with DIN EN 61439-1 and DIN EN 61439-6 for you, for example, for excessive temperature (AC/DC), to determine reactance, impedance, and inductance, magnetic field measurements (AC/DC), or insulation tests (AC).

Multiphysics Simulation

- Magnetic field calculations

- Magnetic field measurements

Thanks to state-of-the-art software and technical expertise, we can simulate various electromagnetic, mechanical, and fluid dynamic phenomena in a single model. Our multiphysics simulations are particularly relevant for solutions in the field of power transmission and assist in the investigation of busbars and busbar systems under electrical load. The simulation options include magnetic fields, heating, losses, and current density distribution. Since the temperature of the busbars has a direct influence on the type of cooling, the operation of adjacent devices, and the losses incurred, this simulation is particularly important for the design of busbars.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

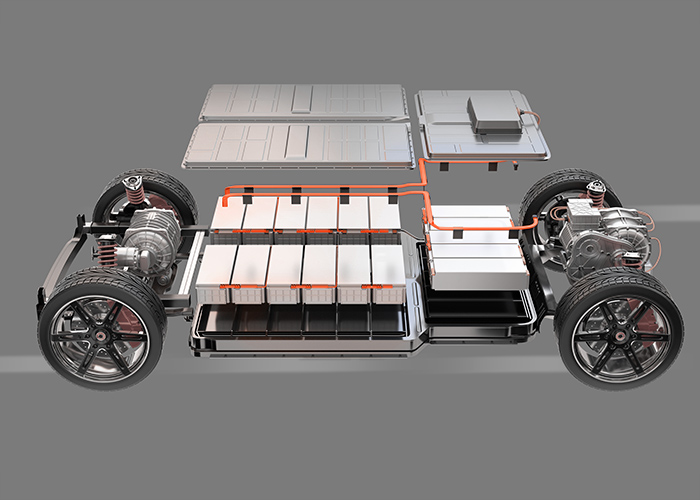

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit