Welding techniques customized

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company according to DIN EN ISO 3834 T3. Our Soldering & Welding techniques are an important core competence for the production of your components and system solutions. In addition to classic welding techniques, we also offer special processes on request – contact us!

The EMS Group is certified according to

DIN EN ISO 9001:2015

Certified Welding techniques for your system solutions

MIG, MAG, & TIG

MIG – Metal Inert Gas Welding is characterized by the use of non-acive gas such as argon. Therefore, MIG welding is considered a cost-effective alternative to other types of welding.

MAG – Metal Active Gas Welding is predominantly used for classic welding operations using CO₂-argon and CO₂-gas. To prevent oxygen from getting into the material, special attention must be paid here to the correct mixing ratio of the two gases.

TIG – Tungsten Inert Gas Welding does not require a wire. Here, tungsten electrodes are melted instead of wire.

Gas-shielded welding

Gas shielded arc welding belongs to the group of fusion welding. Here, the components to be joined are melted at the joints in order to produce the joint after solidification.

Resistance welding and brazing

Resistance welding is performed without the use of filler materials. In resistance welding, the components to be welded are pressed together by opposing electrodes.

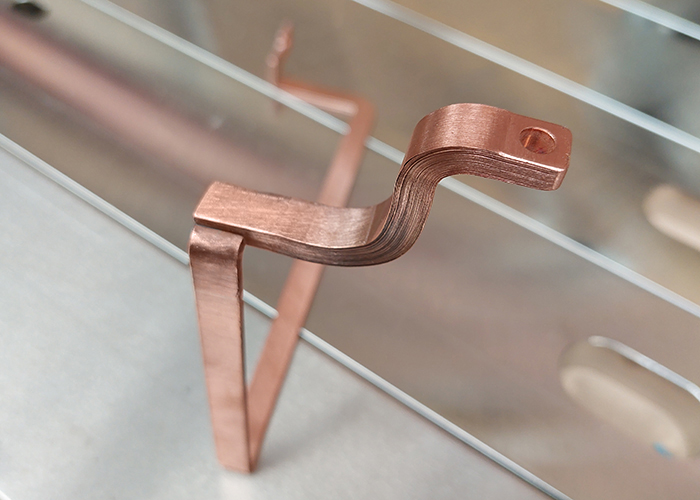

Pressure welding & pressure brazing

Pressure, or resistance welding, is a process in which components to be joined are heated to the melting point and joined by pressing them together. Pressure welding is used primarily in the creation of connections on our flexible fabric & stretch belts.

EMS has the largest presswelding capacity in Europe. This makes us an innovation leader when it comes to creative highcurrent technologies. We are particularly proud of our in-house trained pressure welders.

Robot welding

Robot, or automatic welding is particularly suitable for repetitive operations.

With this automation, a better quality of the weld seam can be achieved from small series. By monitoring process parameters, consistent quality can also be ensured sustainably.

Induction brazing

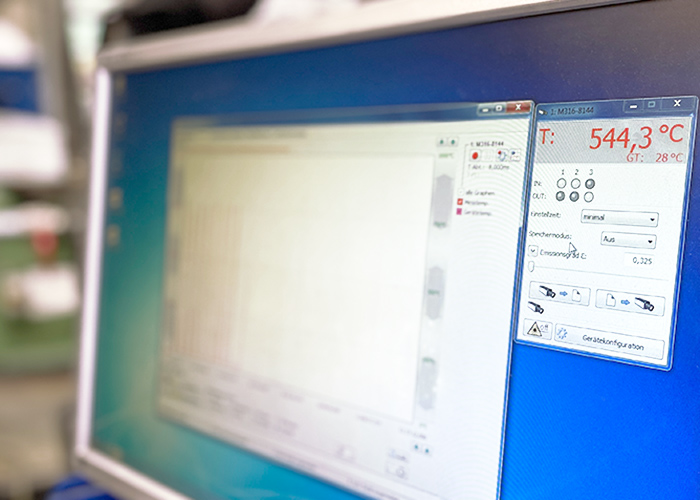

In induction brazing, heat is electromagnetically induced in the workpiece and is particularly well suited for mass production.

For the consistent quality of our components, we also monitor these process parameters digitally.

Rivets connections

The connections of laminated expansion busbars, for example, can also be made by riveting the packages. Cover plates attached to both sides of the connections provide support for the rivets and at the same time form the contact surface.

Today, riveted tapes are only used in a few applications. Otherwise they have been replaced by press-welded bands.

Special processes on request

Our specialties such as electron beam welding, water bath welding, blast cladding and friction welding are used depending on customer requirements and application. Please do not hesitate to contact us.