Innovative Cuponal or CoppAl® busbars

- For Generator & Transformers

- For Switchgears

- Rectifier

- Risers

- Equipotential bonding busbars

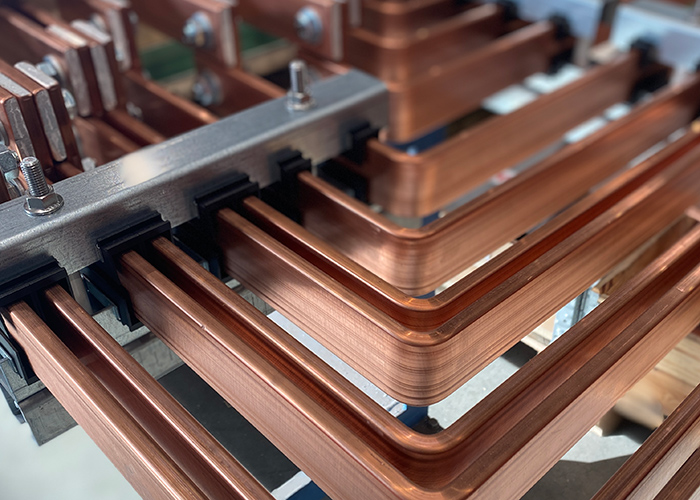

CoppAl® or Cuponal is a bi-metal composite material used as an electrical connection in control cabinets, switchgear and distribution boards.

The machining processes such as drilling, bending, punching and sawing are comparable to those of copper bars.

The EMS Group is certified according to

DIN EN ISO 9001:2015

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBusbar manufacturing with quality & know-how

Our well-coordinated production in multi-shift operation ensures that we can react flexibly and produce your components and units in the desired quality.

In addition, we are able to produce single pieces, prototypes, small quantities, but also large busbars with expansive dimensions and in high quantities at consistently high quality.

The real challenge is not high quality per se – but consistently high quality!

Conductor material CoppAl® (Cuponal)

From cuponal semi-finished products to individual busbars

- Aluminum core EN-AW1350

- Copper sheath Cu-ETP bare

- Tensile strength 130-170 MPa (N/mm²)

Our CoppAl® busbars are composite copper and aluminum busbars, also called CuAL or Cuponal.

The copper sheath encases the aluminum core of the busbars and is inseparably bonded to it. In this way, we can optimally combine the positive properties of highly conductive copper with the low weight of aluminum. CoppAl® busbars are less expensive with the same current-carrying capacity, and are therefore a cost-saving alternative to copper busbars. For the individual design of your busbars, take advantage of our engineering know-how – we look forward to hearing from you!

Current carrying capacity CoppAl® busbars

| Typenbez. / Type | Breite / Width [mm] | Dicke / Thickness [mm] | Länge / Length [mm] | Querschnitt / Cross-section [mm²] | Gewicht / Weight [kg/4000mm] | Scharfe Kanten / Sharp edges [SH] | Gerundete Kanten / Rounded edges [RD] | Strombelastung/ Current rating [A]* 65°C | Art.-Nr. / Item no. |

|---|---|---|---|---|---|---|---|---|---|

| CUAL 20x5x4000 | 20 | 5 | 4.000 | 100 | 1,45 | ✓ | - | 233 | 340042 |

| CUAL 20x10x4000 | 20 | 10 | 4.000 | 200 | 2,90 | ✓ | - | 357 | 340044 |

| CUAL 30x5x4000 | 30 | 5 | 4.000 | 150 | 2,18 | ✓ | - | 325 | 340043 |

| CUAL 30x10x4000 | 30 | 10 | 4.000 | 300 | 4,37 | ✓ | - | 481 | 340041 |

| CUAL 40x10x4000 | 40 | 10 | 4.000 | 400 | 5,81 | ✓ | - | 611 | 340008 |

| CUAL 50x10x4000 | 50 | 10 | 4.000 | 500 | 7,26 | ✓ | - | 736 | 340001 |

| CUAL 60x10x4000 | 60 | 10 | 4.000 | 600 | 8,71 | ✓ | - | 848 | 340009 |

| CUAL 80x10x4000 | 80 | 10 | 4.000 | 800 | 11,62 | ✓ | - | 1.074 | 340010 |

| CUAL 100x10x4000 | 100 | 10 | 4.000 | 1.000 | 14,52 | - | ✓ | 1.282 | 340002 |

| Strombelastung/ Current rating [A]* 65°C |

* Current load values: Ambient temperature 35 °C, AC current AC.

Heating of the busbar as a function of: Current intensity, ambient temperature, heat dissipation, type of routing, installation, application Multiplication factor 1.72 when using 2 rails, multiplication factor 2.25 when using 3 rails in parallel arrangement.

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ Processing standard DIN EN 13601

+ Connecting pieces in welding systems

+ Individual perforations

+ Bending

+ Deburring

+ Punching

+ Sawing

+ Soldering

+ Personalizations

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit