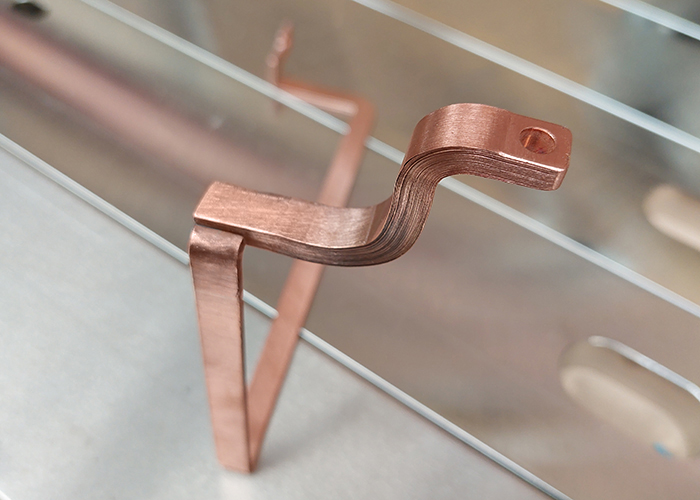

Battery Busbars for Accumulator Packs

- Solid or flexible

- For serial or parallel connection

An accumulator or battery pack consists of several accumulator or battery cells. These cells are connected either in series or in parallel. To transmit current between the individual cells, we manufacture Battery Busbars, or flexible busbars for short, made of bare, nickel-plated, tin-plated or silver-plated copper Cu-ETP, cupal or aluminum.

Application areas of such battery packs: automobiles, quads, motorcycles, buses, railroads, commercial vehicles, funsport-mobiles, pedelecs, segways, storage technology for renewable energies, energy supply and many more.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBattery Busbars Conductor Material & Insulation

Insulation of Battery Busbars

To protect adjacent components, battery busbars are insulated according to your specifications.

Since the type, size and number of cells of the battery play an essential role in the design of the battery connectors, we design and manufacture your battery flexible busbars with individual bends for path & vibration compensation, cross-sections, and insulation.

If required, we will be glad to provide experts for the engineering and design of your custom battery busbars.

Sheets or lamellas as conductor material

- Solid or as connected lamellas

- Copper Cu-ETP & OF-Cu

- Cupal

- Aluminium EN-AW6082

For current transmission between the individual cells, we manufacture battery busbars made of bare, nickel-plated, tin-plated or silver-plated copper, cupal or aluminum.

The EMS Group is certified according to

DIN EN ISO 9001:2015

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ Fabrication & Manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assemblies

+ Further processing

+ Personalizations

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!