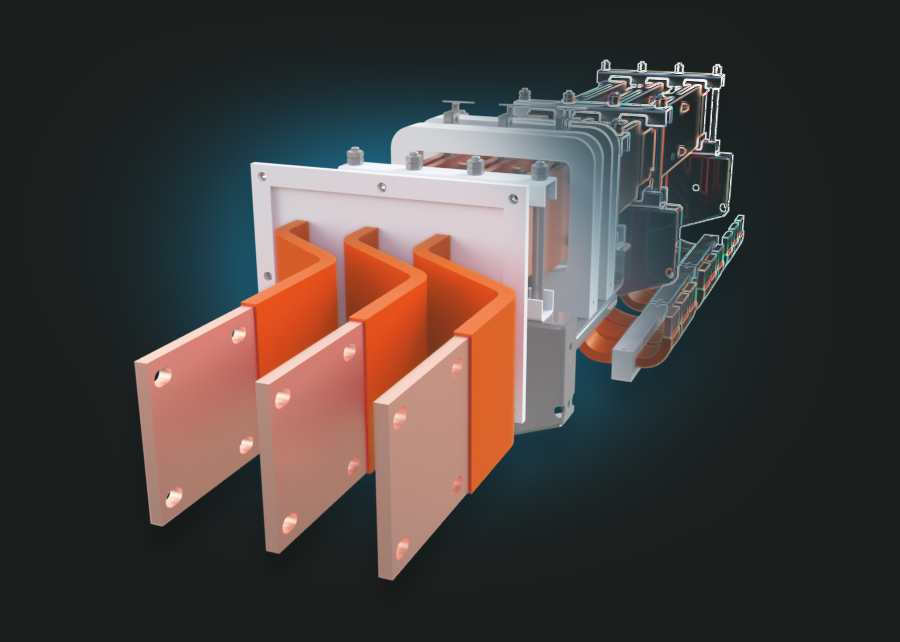

Solutions for Busbar Assembly Units

EMS stands for holistic services – Engineering and Manufacturing Solutions for Busbar Assembly Units is therefore one of our core competencies. In addition to our technically mature individual components, we also offer customized support for all stages of the development process of an assembly.

If required, we can already assist you with the conception, technical design and calculation of your customized assembly. Our experienced engineering experts and designers and state-of-the-art technologies, always ensure results in line with your requirements during analysis, calculation, simulation, test engineering and manufacturing. We meet every challenge – contact us!

The EMS Group is certified according to

DIN EN ISO 9001:2015

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Made in Germany & Poland - all from one source

Consulting & Customized Engineering

- Focus on Busbar Assembly Units

- High current technology

- Holistic system solutions

We are your specialist for project management and engineering services in the field of design and engineering of Busbar Assembly Units.

The entire engineering process is characterized by direct and intensive exchange with our customers. Thereby, we guarantee that all components meet the defined quality requirements. If required, we also take over the assembly of components on site in addition to planning & manufacturing.

Manufacturing with maximum precision

- Modern processes & machines

- Welding know-how

Thanks to the many years of experience of our employees and modern machinery, our well-coordinated manufacturing team in multi-shift operation ensures that we can react flexibly and manufacture your components and assemblies in the desired quality. EMS Elektro Metall Schwanenmühle GmbH is a certified welding company according to DIN EN ISO 3834 T3 with a wide range of soldering & joining techniques. No matter how customized your requirements are, EMS has the right solution and is equipped to handle your order.

EMS Quality Management

- DIN ISO 9001

- CE

- UL

EMS quality management is certified according to DIN EN ISO 9001:2015. With CE and UL certification, we also give top priority to environmental protection and safety. We make the difference for your Busbar Assembly Units by delivering total quality.

Custom assembly of subassemblies

- Partial or component assembly

- On site or ex works

We offer the assembly of subassemblies or complete busbar assemble units – pre-assembled ex works or at your site.

Our experienced technicians and assemblers accompany you from development to assembly. Our optimized capacity planning ensures that assemblies are assembled and delivered within the specified time.

Flexible logistics for dynamic markets

- Packaging according to demand

- Worldwide shipment

- Just-in-time

Our well-rehearsed logistics team is competent, efficient, and service-oriented. The shipping of your Busbar Assembly Units is in good hands with us!

We design Busbar Assembly Units

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.