Movable Expansion Busbars

- Good flexibility

- High quality

- Long life

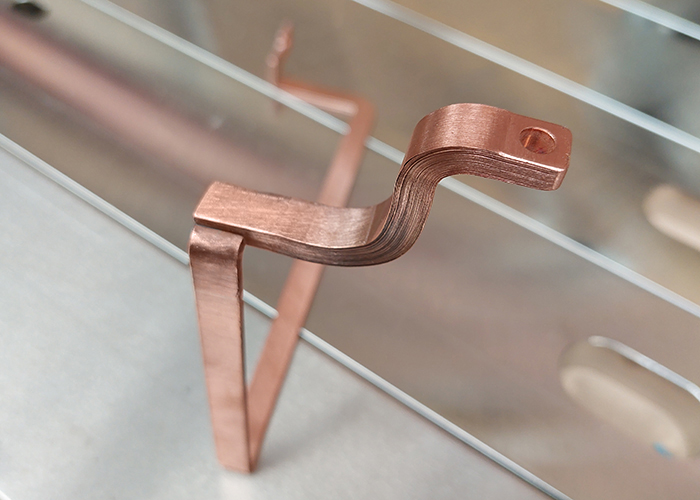

Our Laminated Expansion Busbars are used as expansion and vibration compensation within busbar connections. They are also installed as flexible current transmission elements in machine parts, vehicles and switchgear.

The engineering of an Expansion Busbars is influenced by the current intensity, the current path, the connection material, the flexibility requirements and the installation conditions such as ambient temperature.

Expansion Busbars Conductor Material & Connections

Conductor Material of Expansion Busbars

Depending on the required current values, mainly copper and aluminum strips are used, but also combinations of both materials.

- Copper Expansion Busbars (DBCU) made of Cu-HCP copper fins of thickness 0.2 mm with pressure welded connections of the same material.

- Aluminium Expansion Busbars (DBAL) made of EN AW-1050 0.3 mm lamellae with MIG-welded EN AW-6060 connections.

If required, we also carry out surface refinements. Please feel free to contact us!

Connections Expansion Busbars

Press-welded connections have excellent conductivity due to a perfect molecular bond. The connection surfaces can be drilled, milled and bent.

Shielding gas welded connections are locally melted by means of an electrically generated arc. The shielding gas prevents oxidation of the molten metal.

By soldering the connections, even very complicated designs can be realized. Depending on the application, various brazing alloys and processes are available.

The EMS Group is certified according to

DIN EN ISO 9001:2015

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFlexible Expansion Busbars

The flexibility of Expansion Busbars compensates for expansion when busbars heat up.

Expansion Busbars also prevent damage to device connections in the event of switching vibrations, for example.

The press-welded connections have low contact resistances and are easy to install.

Configure Expansion Busbars correctly

Expansion Busbars customized

EMS engineers and manufactures copper and Aluminum Expansion Busbars with technically advanced connections customized on request.

Our Expansion Busbars are manufactured according to DIN 46276, part 1. The current carrying capacity is designed according to DIN 43670 (air temperature 35°C / rail temperature of 65°C).

Example description: DBAL40/5/60-220 S

Material: DBAL für Aluminium oder DBCU für Kupfer

Width: 40 mm

Thickness: 5 mm

Connection length: 60 mm

Total length: 220 mm (in the bent state, correspondingly longer in the stretched state).

Shape: S (similar to a sine wave)

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ MIG & TIG welding

+ Pressure welding

+ Explosive cladding

+ Electron beam welding

+ Aluminothermic welding

+ Brazing

+ Customized lengths

+ Personalizations

+ Packaging according to customer specifications

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit