High Current System Solutions

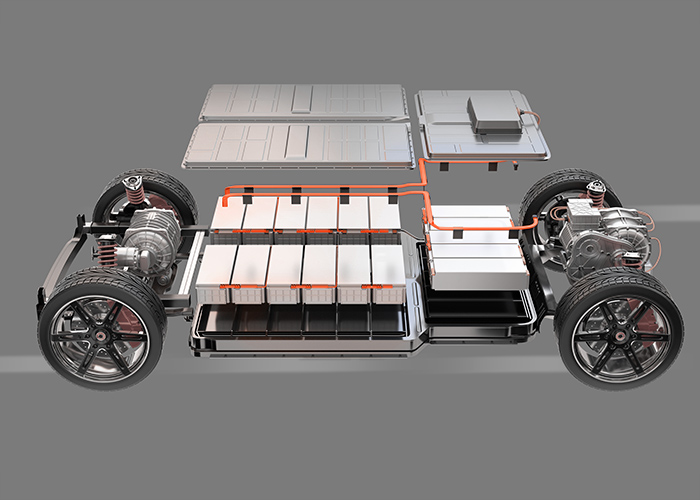

- Assembly Units from components

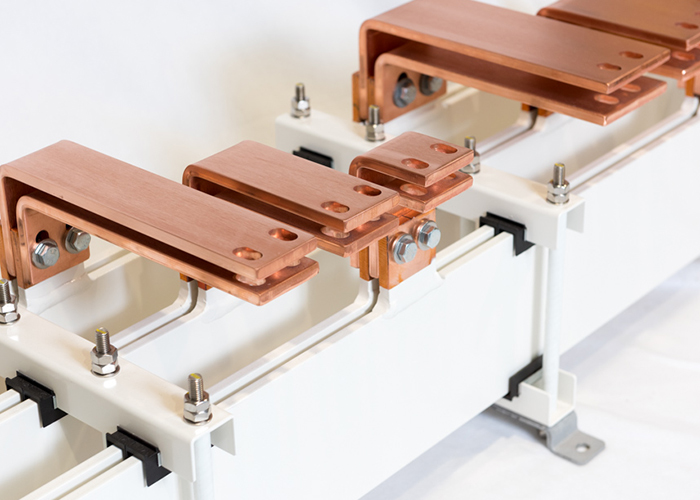

- Vision®Bar Busbar Systems

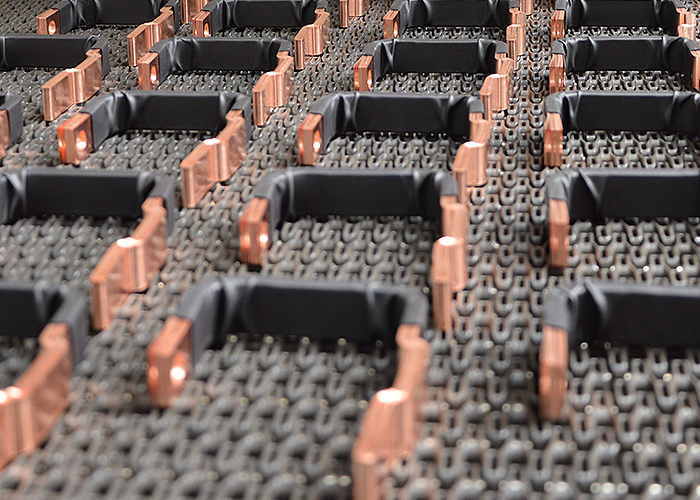

- Highly flexible braided busbars

- Flexibles like laminated expansion busbars or Isoflexx®

- Solid Copper, Aluminum & CoppAl® busbars

- Flat copper, aluminum & cupal sheet busbars

EMS stands for holistic system solutions – solving complex tasks is therefore one of our core competencies. In close cooperation with our customers, we engineer projects systematically and implement them efficiently. The optimization of functionality is just as important as infrastructural, production and economic aspects. The result is customized solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail. We rise to every challenge!

On December 4, 1754, Heinrich Klug received permission from his sovereign to build a grist mill above the so-called Geiselberg Mill, which belonged to the Electoral Palatinate, on a piece of land he owned. Heinrich Klug thus laid the foundation for a long milling tradition in the Klug family.

Manufacturing for the production of apparatus and vessels for the chemical industry. Acquisition of knowledge and skills in welding copper and aluminum. Production of large busbars and expansion strips for chlorine, zinc, aluminum and other electrolysis. Development of special technologies, such as pressure welding of copper laminations.

Laminated expansion busbars from Schwanenmühle proved to be a profitable addition to the product range of ERICO GmbH, which became the largest customer of Alois Weiser KG.

ERICO GmbH buys out Alois Weiser KG and relocates its headquarters to Schwanenmühle. Production capacities are significantly expanded with the construction of new halls. Years of organic and dynamic growth allow the number of employees to rise to 160.

With the foundation of Vision®Electric GmbH, the development, manufacturing, and installation of busbar systems in the range from 32A to 300 k.A. is outsourced to an independent profit center.

The two ERICO authorized signatories Kurt Mutter and Dr. Wolfgang Reiser take over the Schwanenmühle production facility and establish an independent company, EMS Elektro Metall Schwanenmühle GmbH. The core competence is the further development, production, and manufacturing of laminated expansion busbars as well as special electrotechnical products.

In view of the positive business development, EMS diversifies further and establishes a third company: SPS Standard Produkte Schwanenmühle GmbH. It engineers, manufactures and sells standard products for the electrical engineering sector, including insulated laminated busbars (Isoflexx®), highly flexible busbars (Ultraflexx®) and earthing braids (mainly for switchgear construction).

With the foundation of EMS Elektro Metall Spezialprodukte Sp. z.o.o., the company expands to Poland and thus extends its scope of action by a second production site.

With buzzbar an online portal for digital quotation & purchase processing, manufacturing & logistics of standard busbars, saw cuts & semi-finished products according to buzzbar standards was created.

Today, EMS Elektro Metall Schwanenmühle GmbH with its brands EMS, SPS, buzzbar and Vision®Electric is known for customized full service in the field of High Current Technology.

Special electrical engineering products from Schwanenmühle

Our vision

- 415 employees of the EMS Group

- 14,500 m² production area

Holistic system solutions for High Current Technology are our passion.

Reliability, quality, and sustainability are our claim. As a strategic partner, we are the first choice for our customers.

Our mission

Our orientation is an excellent understanding of customers and markets. Our constant curiosity is a driving force for our innovative and technological competence. It is a prerequisite for exquisite and holistic solutions in the field of high current technology.

Our company-wide understanding of values is the basis for an extraordinary sense of unity. We see ourselves as a permanently learning organization. Based on a broad positioning of the company, a best-in-class value chain and the intelligent use of growth potential, we want to shape our future sustainably.

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

The EMS Group is certified according to

DIN EN ISO 9001:2015

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!

Quality management

The quality management of EMS is certified according to DIN EN ISO 9001:2015. With CE certification, we also give top priority to environmental protection and safety.

The commitment to the strictest standards shows that we do not pay lip service to our quality claim. Rather, it is a continuous motivation. Because with holistic high quality, we make the decisive difference.

For our customers, our employees, and our company. We are proud of this.

Corporate Policy

Quality can only be manufactured in an environment in which responsibility for employees, society, and the environment is perceived consciously and sustainably.