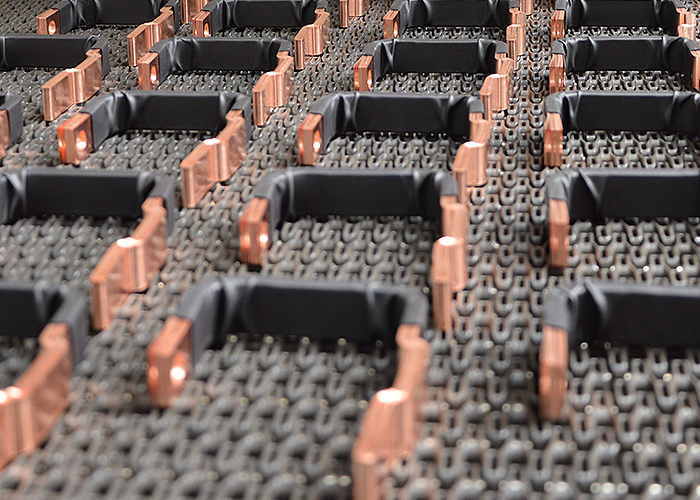

Busbars for Energy storage, power supply & grids

The share of renewable energies in Germany is increasing every year. While the share was still at 6 percent in 2000, it is expected to rise to over 80 percent in 2050. However, due to the time of day and weather conditions, wind energy and solar plants do not constantly and evenly feed electricity into the grid. This is why energy storage systems are essential for the energy transition. To secure the energy supply in the long term, our grids will have to be massively expanded in the coming years. More than 7,000 km of networks needs to be optimized, reinforced or newly built for this purpose. To this end, the entire infrastructure must be upgraded to meet the requirements of the future. Whether busbars for transformers, HVDC rectifiers or converters – our components and system solutions can make the decisive difference for you. Contact us, we will be happy to advise you!

System solutions for Energy storage, Power Supply & Grids

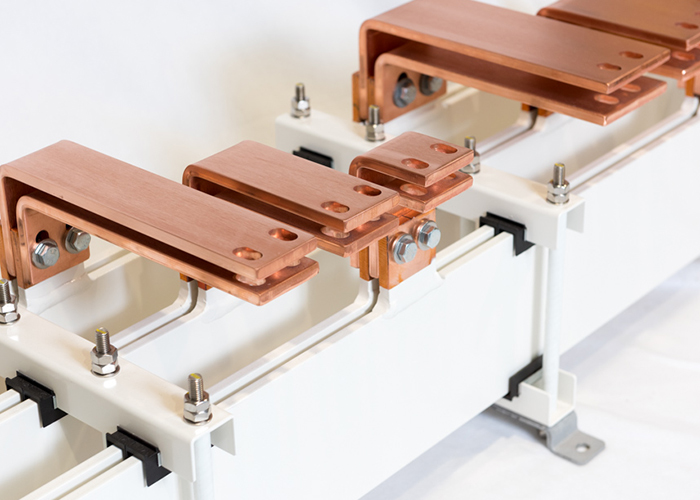

Components for Stationary Energy Storage

- Home storage 63 - 1,600 A

- Large battery storage 1,200 - 9,000 A

- Storage for C&I (Company & Industry) 10,000 - 300,000 A

After power generation, this energy can be temporarily stored and retrieved as needed thanks to stationary storage.

Stationary storage enables the large-scale integration of renewable energies across all application areas. Depending on requirements, battery systems can be designed from a few kWh up to GWh. The greatest benefits include ecological and economic aspects, such as CO₂ savings and reduced electricity costs.

System Solutions for Power Supply & Grids

To adapt the network infrastructure to the new requirements, it can not only be expanded, but also optimized and strengthened. In this way, the existing transmission capacities can be increased or used more efficiently.

For safe power transmission within your equipment, such as transformers, converters or HVDC rectifiers, we develop and manufacture individual busbar system solutions according to your specifications. Please contact us!

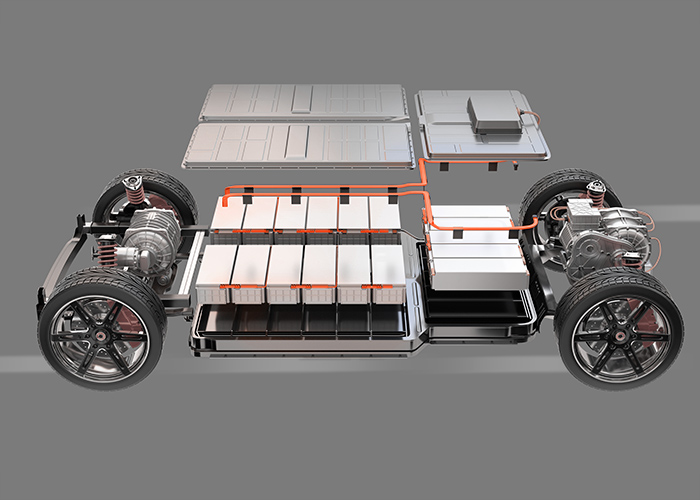

Components for charging infrastructure for E-vehicles

- High current carrying capacity

- Safe insulation

Charging stations for electric vehicles must be able to transfer high currents, especially fast-charging stations. The busbars must be dimensioned accordingly to avoid overheating. Busbars at charging stations must therefore be securely insulated or protected to avoid short circuits and other hazards.

To minimize possible energy losses and thus increase the efficiency of the charging station, it is also important to have low contact resistance at the connection points.

System solutions for more energy

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

FAQs Busbars for containerised Energy Storage

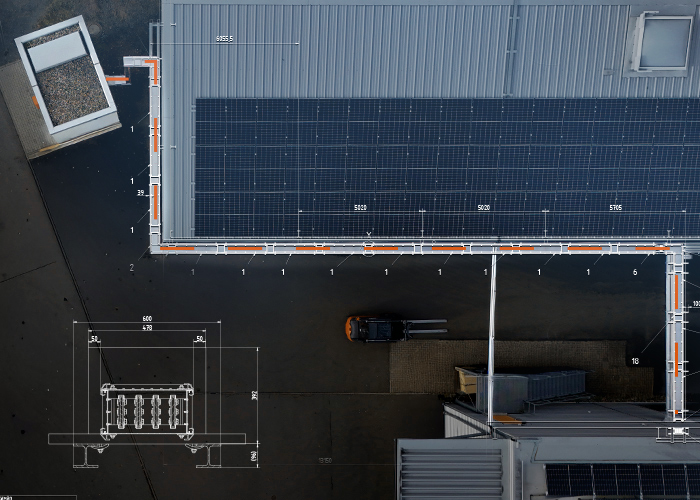

Due to the modular design of containers and the associated ease of installation and commissioning, they are often used in remote locations. If you are planning such a project, we will be happy to support you in the engineering and manufacturing of reliable busbar solutions for utilities of all kinds.

In addition to the battery racks and the accumulators, battery containers usually also contain the complete control technology, such as transformers, inverters in solar systems, rectifiers in charging stations or grid stabilizers. In combination with decentralized energy generators such as solar plants, wind power or even hydropower, they usually serve as a self-sufficient energy solution. Our busbar systems are used in battery containers as electrical components in power distribution systems to transport electrical energy from one source to various consumers.

“Power-to-gas” (PtG) is a process in which surplus electrical energy is converted into hydrogen or methane. This can be stored or used as an energy carrier for various applications. For this conversion process, electrical components such as control cabinets, transformers, rectifiers and electrolysers are used in a PtG plant. To make the necessary electrical connections, these components are connected with busbars.

Emergency power battery containers are used as emergency standby units (NEA) to supply critical consumers with power in the event of a power outage or temporary overload of the power grid. With comparatively little construction effort, even systems in difficult locations can be safely supplied.

Mobile battery containers can be used as a temporary power supply on construction sites or at events to provide additional energy when the existing power infrastructure is not sufficient.

Battery containers can also be used as grid balancers in smart energy grids. They store surplus energy from renewable sources and feed it back into the grid when needed.

To ensure a stable and sustainable power supply, battery containers can be used in combination with other energy sources such as solar or wind power and thus also be used as a hybrid power supply.

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

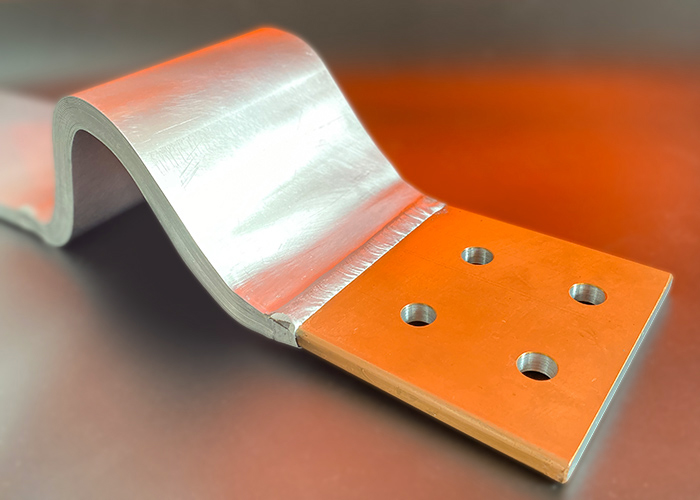

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

online-Meeting

Book your consultation appointment now:

Carsten Getta

P: +49 6307 9116 616

M: +49 152 283 110 10

E: cgetta@ems-power.com

You would like to receive an offer directly? Then simply use our form – we look forward to hearing from you!

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.