Engineering High Current Busbars

EMS stands for holistic performance – solving complex tasks is therefore one of our core competencies.

In addition to our technically mature components, we also offer customized support for all stages of the engineering process. If required, we can already assist you in finding solutions and designing prototypes, and accompany you from technical design and calculation through to series production readiness. Experienced engineering experts and designers as well as state-of-the-art technologies ensure 100 percent demand-oriented results in analysis, calculation, simulation, test engineering and prototype production. We rise to every challenge!

Rooted in tradition. Driven by progress.

For over a century, International Wire, Hussey Copper, EMS Elektro Metall Schwanenmühle and Special Corde have been trusted names in the conductor and copper processing industry, synonymous with quality, reliability and innovation. Known for precision, performance and partnership, these companies have helped form the backbone of modern electrical infrastructure.

As part of Pantheon Electric, its tradition is now not only being continued, but even expanded.

The EMS Group is certified according to

DIN EN ISO 9001:2015

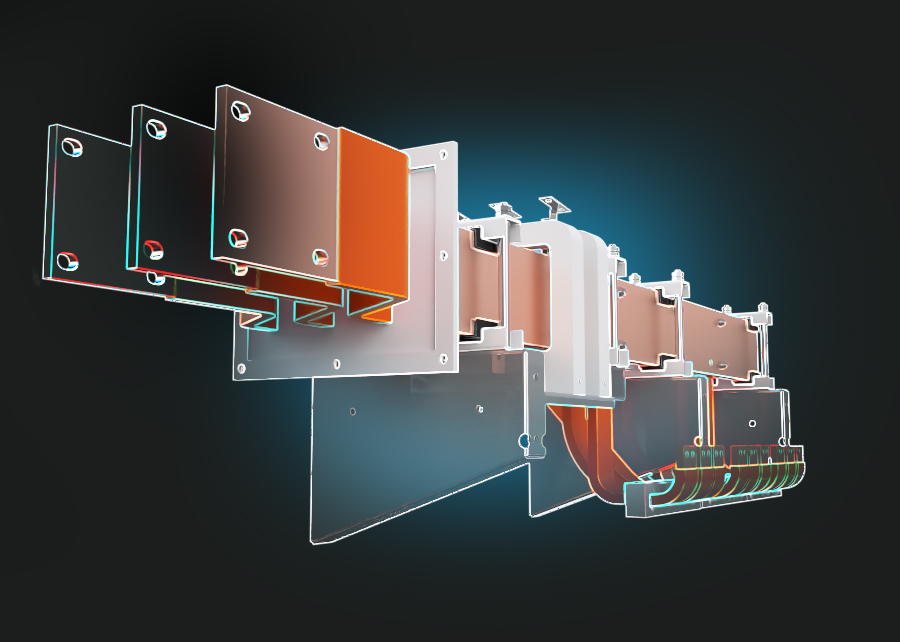

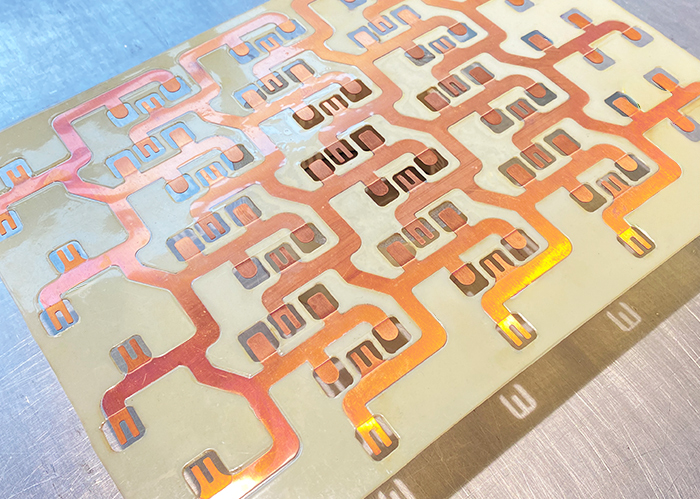

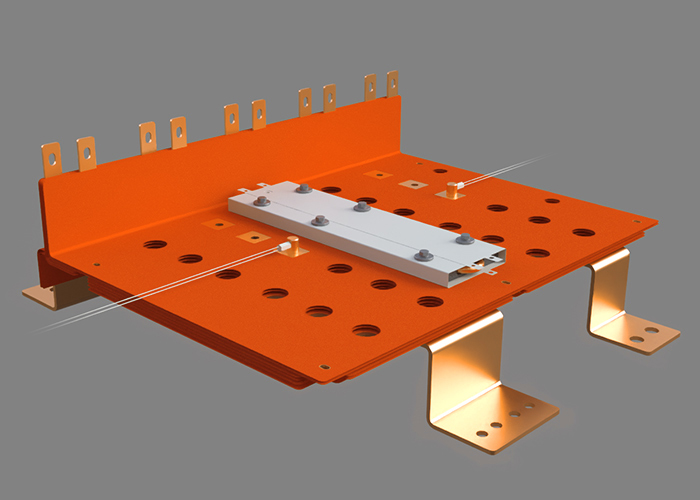

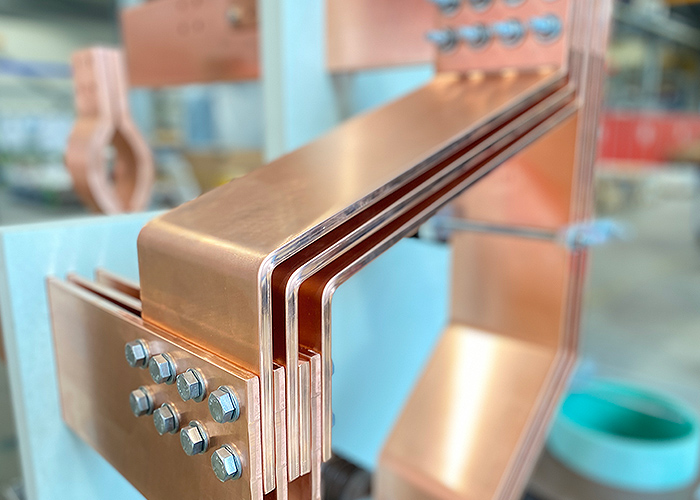

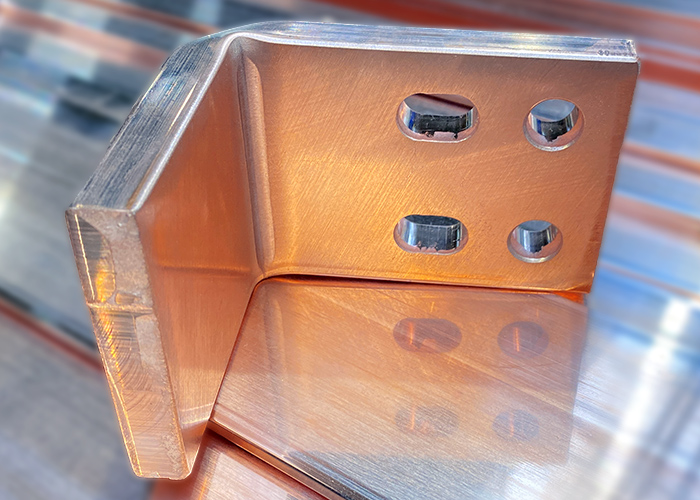

Special electrotechnical high current busbars

EMS Elektro Metall Schwanenmühle GmbH

- Customized high current technology

- Holistic system solutions

- Customized manufacturing, assembly & logistics

- Focus on busbar assembly units

EMS is your professional when it comes to customized high current busbars, integrated system solutions, customized manufacturing, individual engineering and the assembly of components.

Customized Engineering & Manufacturing

- Custom High Current Busbar Systems

- Project management, engineering & design

- Manufacturing, logistics & assembly

We are your specialist for project management and services in the field of design and engineering!

EMS Quality Management

The EMS quality management is certified according to DIN EN ISO 9001:2015. With CE, RoHS and UL certification, we also give top priority to environmental protection and safety.

With holistic high quality, we make the decisive difference.

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!

Busbar Blog by EMS

Our busbar solutions are very important for many industries. From electric cars to computer centers, busbars are more than just copper. We talk about these high-tech parts on our busbar blog.

The EMS JobPortal.

Are you looking for a new job? Are you more of a developer and creator than a follower, do you like to think outside the box and see change not as a threat but as an opportunity?

Then apply now!