From simple components to complex solutions

Our portfolio ranges from simple component production to fully pre-assembled assembly units.

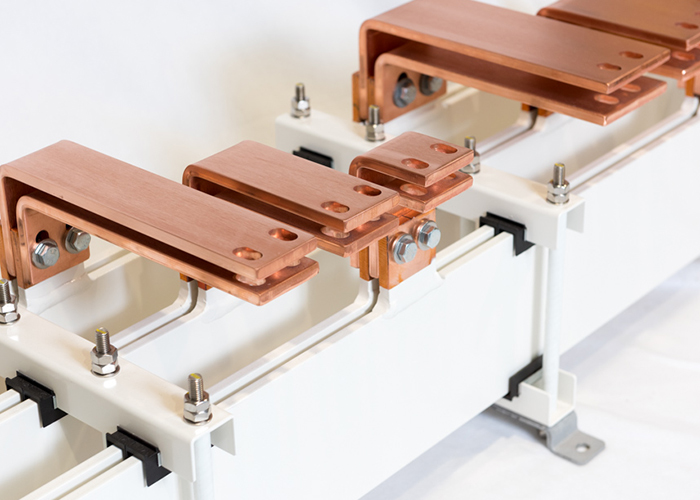

This also includes complete switching components for circuit breakers from 1000 A to 6300 A as well as complex solutions, such as for the wind industry and e-mobility. The entire development process is characterized by direct and intensive exchange with our customers. In doing so, we ensure that all components meet the defined quality requirements. If required, in addition to engineering and manufacturing, we also take care of component assembly ex works or on site.

Reduce your planning, time and logistics costs thanks to our experience – contact us!

Component installation to individual assembly units

Installations & Pre-assembly ex works

Save your own resources and use our service for subassembly. We offer the pre-assembly of components or complete solutions, ex works.

Our experienced technicians & assemblers accompany you from engineering to installation. Benefit from our economical way of thinking and years of experience in the field of high-current connectors.

Our optimized capacity planning ensures that assembly units are assembled and delivered within the specified time. We also carry out the functional and final tests of the assembly units.

On-site Installations

- Logistics & installation

- Aluminum welding

- Magnetic field & temperature measurement

- Insulation test

In addition to the engineering and manufacturing of our system solutions, we also offer on-site assembly work.

During our on-site installation of your system solutions, we focus on the rapid completion of the project as well as the corresponding safety requirements.

The EMS Group is certified according to

DIN EN ISO 9001:2015

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!