Busbar Systems for Industry

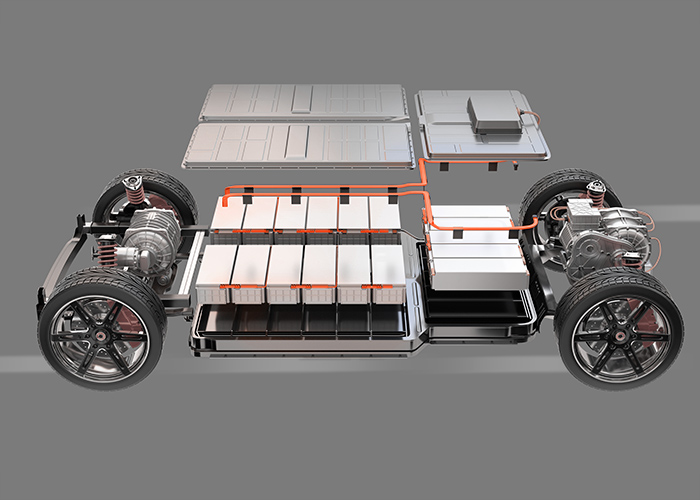

EMS has many years of experience in the engineering, manufacture and installation of innovative Busbar Systems. With our Vision®Electric brand, we have already demonstrated our expertise in numerous projects, including in the data center market. Especially for harsh and industrial environments, we engineer and manufacture Busbar Systems from 1,200 to 300,000 amperes (A) according to your specifications and requirements. Our focus is on customized solutions, excellent service and a very good price-performance ratio. Flexibility, reliability, and customer satisfaction are our top priorities. In addition to data centers, Vision®Electric‘s field of application also includes complete switchgear components for circuit breakers and complex solutions, e.g., for the Basic materials’ industry, the Wind industry and e-Mobility.

The right system for your requirement

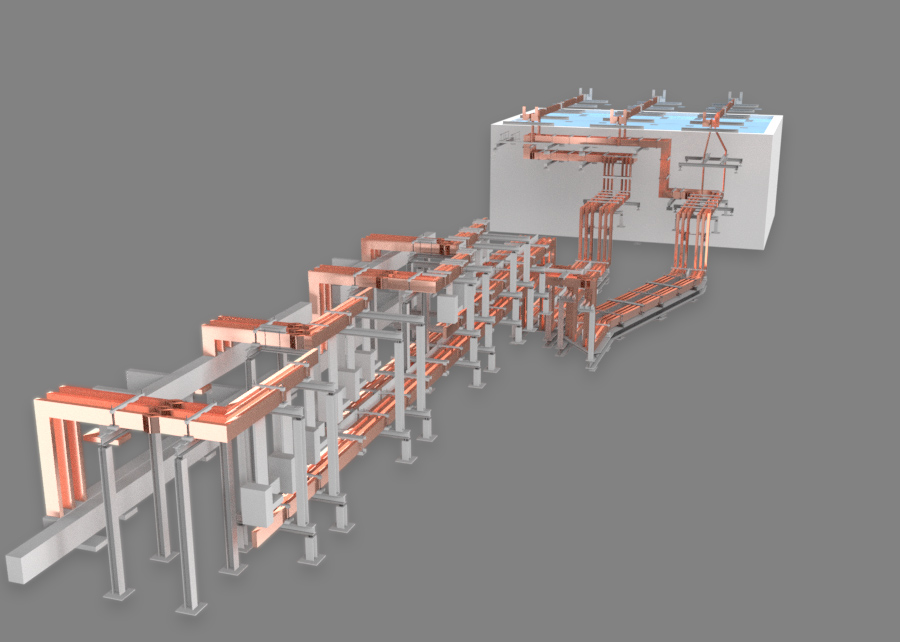

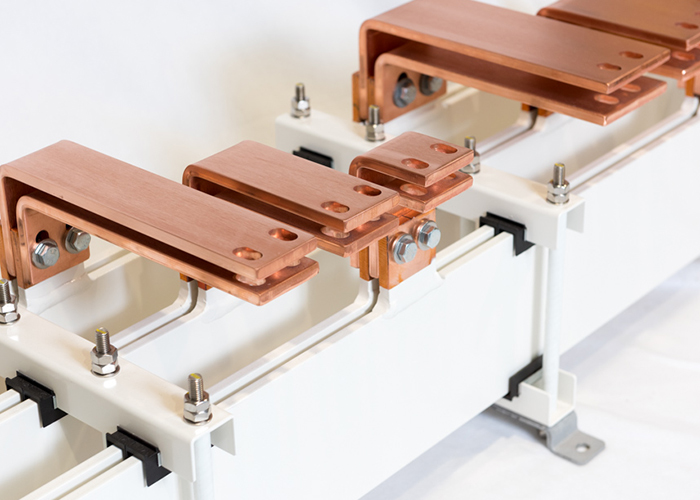

Vision®Bar Module System

- 1,200-10,000 amperes (A)

- Copper (CU) or Aluminum (AL)

Vision®Bar is the safe and reliable Busbar System specially engineered for connecting power generators to switchgear or large consumers and load distribution panels.

The unique combination of fixed and flexible components allows Vision®Bar to adapt to a wide range of installation conditions.

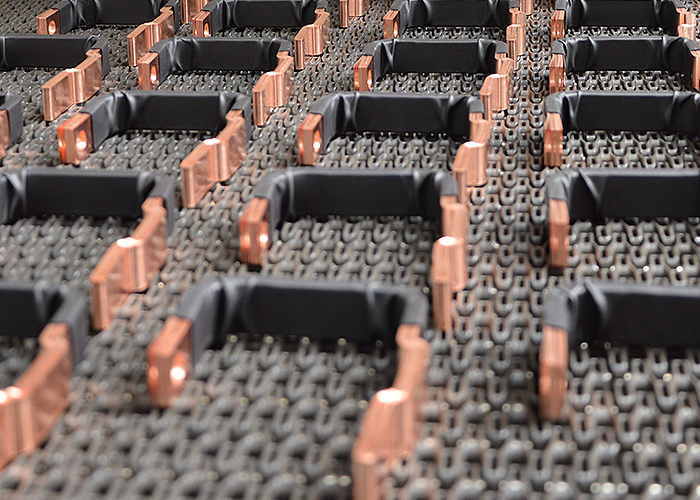

IndustryBars for more power

- 10,000-300,000 amperes (A)

There are many applications for high-power Busbar Systems, in most cases for direct current. However, all applications are customized solutions based on the respective project requirements, such as for chlorine electrolysis with 18,000 amperes (A) or aluminum electrolysis with 180,000 amperes (A).

Special knowledge and experience are required to carry out the detailed design in order to optimally combine the respective plant technologies with the various manufacturing processes and the right materials. We will be pleased to advise you!

Vision®Rail

- 63-1,600 amperes (A)

Vision®Rail‘s continuous busbar cross-section allows the use of a variety of feeder and distribution units at any location. Valuable floor space is now available for server racks instead of switchgear distribution panels. Two parallel busbar systems supply the server racks with both main and emergency power. We also offer pluggable tapp off boxes for our standard Vision®Rail Busbar System for area-wide power distribution in data centers. Our Vision®Rails have part numbers such as VR-AD 401252.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

EMS Core Competencies

All from one source

Reliability, quality and sustainability are our claim. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

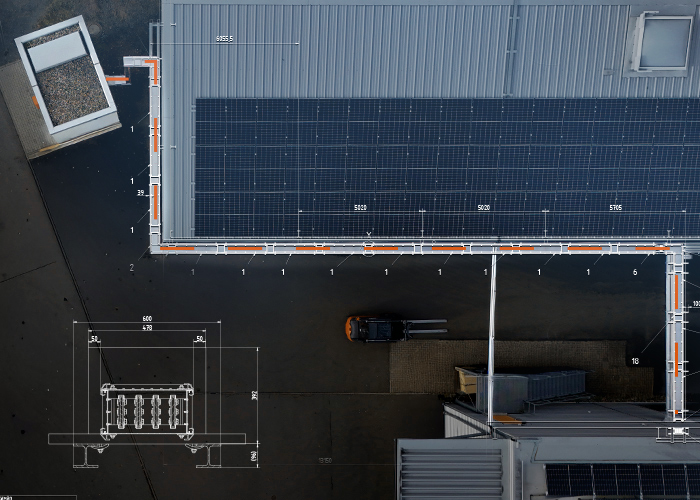

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

We design your Busbars

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.