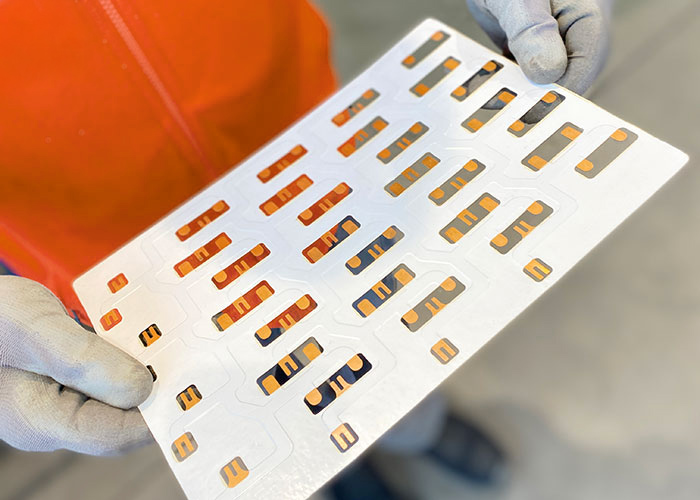

Laminated busbars with precise contours

- Reduction of system costs

- Reliability improvement

- Capacity increase

- Elimination of wiring problems

- Reduction of impedance and inductance

The growing demand of renewable energy, electric vehicles, home and building automation, leads to an ever-increasing need for laminated busbars. Our laminated busbars can be found in drive systems for railroad applications, in wind and solar inverters, in commercial frequency converters, and in large UPS systems or other power supply equipment.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBusbar production at the next level

On our laser punching machine, we process sheet metal formats of maximum 1250 mm x 2035 mm in laser punching mode every day.

The integrated laser creates precise contours and the punching tools enable pull-throughs, roll beading, offsets and signatures in no time at all.

No matter how individual your requirements, our engineering & manufacturing have the right solution for your job – contact us now!

Characteristics of the laminated busbars

Conductor material & insulation laminated busbars

Flat conductive sheets as conductor material

- Copper Cu-ETP & OF-Cu

- Cupal

- Aluminium EN-AW6082

We use copper (CU-ETP), aluminum or cupal sheets as conductor material. All materials can be tin-plated or nickel-plated according to requirements and application.

We process the thin copper sheet parts in laser punching operations in formats of up to 1250 mm x 2035 mm.

Insulation by lamination

- PET

- PEN

- PI

- NOMEX

- MYLAR A

Laminated insulations are particularly advantageous for complex busbars. EMS uses only high-quality and hard-wearing foil material to laminate the busbars. Further insulations anytime on request!

The EMS Group is certified according to

DIN EN ISO 9001:2015

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ Formats up to 1250 mm x 2035 mm

+ Individual perforations

+ Precise contours

+ Pull-throughs, roll beading, bending

+ Personalizations

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!