Busbars for basic material production

- Aluminum Smelters & Glassworks

- Cement & Paper Industry

- Nickel, graphite & zinc industry

For industrial customer requirements

Busbar systems with Vision®Electric

- Vision®Bar

- IndustryBar

- Vision®Rail

Under the Vision®Electric brand, we primarily manufacture innovative busbar systems in the 1200-300,000 ampere range, specifically for harsh and industrial environments in the primary industry according to customer specifications.

Resistant aluminum busbars

- AlMgSi0,5 [EN-AW6060] or AlMgSi1 [EN-AW6082]

- E-AlMgSi0,5 [EN-AW6101B] on request!

Aluminum with a high purity has excellent electrical properties. Therefore, aluminum is used both as a conductor of electricity and to optimize heat transfer at contact surfaces. Under given environmental conditions, pure aluminum produces a closed aluminum oxide layer (Al203). This property makes aluminum highly resistant to corrosion. By optimally designing the cross-sections, the arrangement, and the insulation material, costs can be reduced and a high level of operational reliability can be achieved.

System solutions for electrolysis

- Chlorine electrolysis, Copper electrolysis & Hydrogen Electrolysis

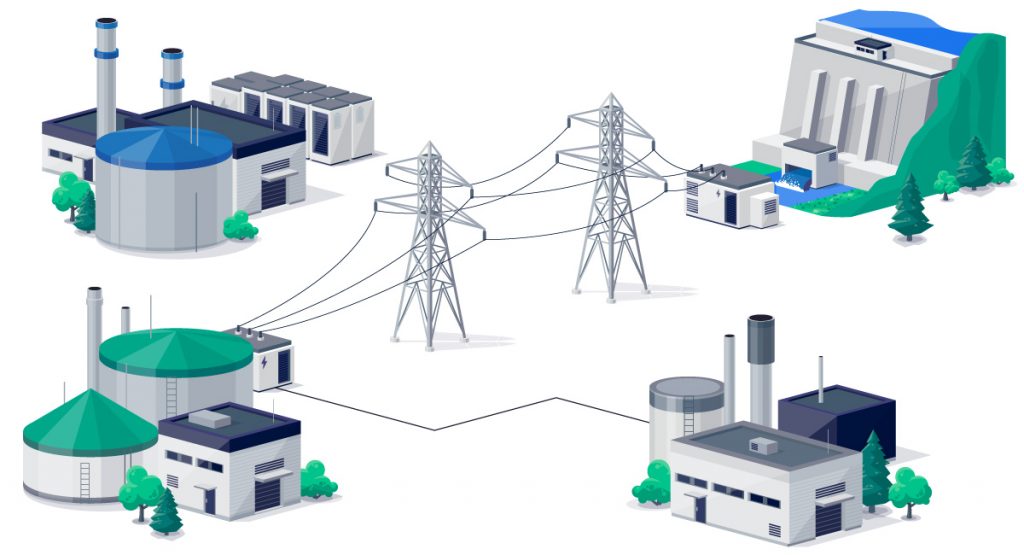

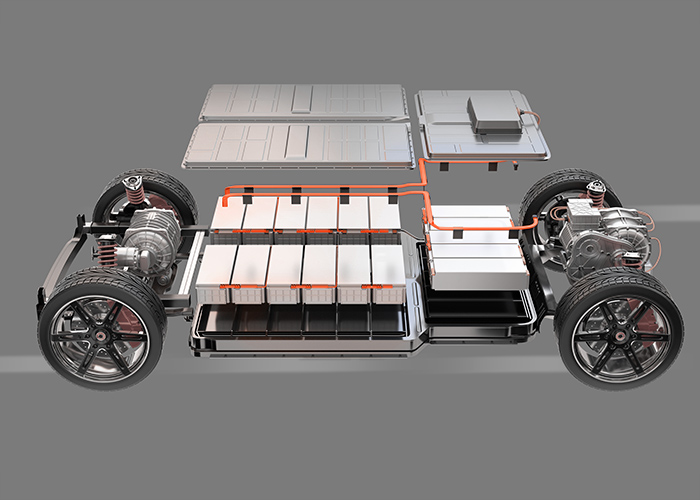

Busbars are mainly used in power distribution, centralized or decentralized power generation and energy-intensive processes such as electrolysis (hydrogen electrolysis). We engineer your environment-adapted and corrosion-resistant high-current connections, always taking into account magnetic fields, pollution levels and chemical compatibility – even or especially for existing infrastructure. With our many years of experience, EMS Elektro Metall Schwanenmühle is your competent partner for electrical busbars in the field of high-current technology – even for very high currents of 10,000–300,000 amperes!

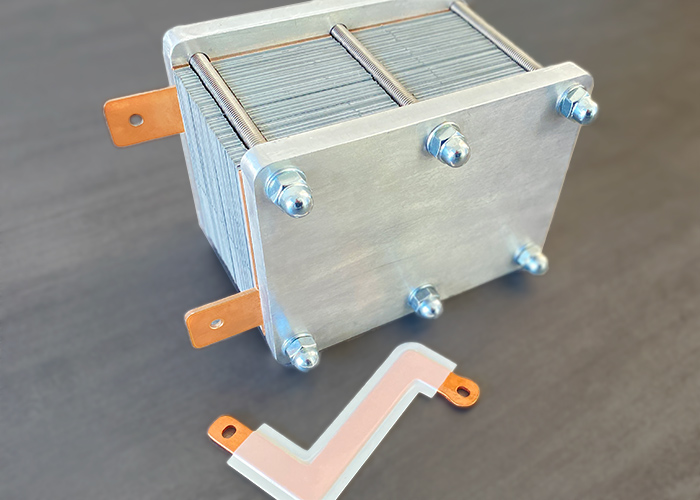

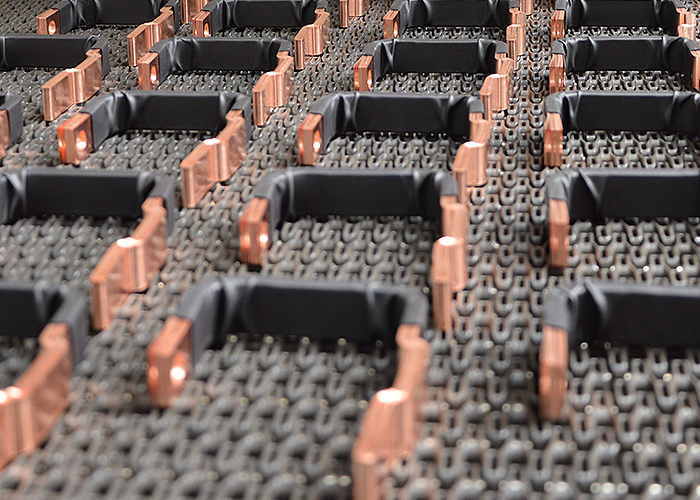

FAQs Busbars for hydrogen stacks

A hydrogen stack, also called a fuel cell stack, is an arrangement of several fuel cells connected in series or parallel to generate higher electrical power. A hydrogen stack forms the heart of a fuel cell, since the actual electrochemical process that generates electricity takes place in it. A hydrogen stack is composed of a series of cells, each of which consists of electrodes, an electrolyte and a catalyst. A single cell usually consists of an anode (negative charge) and a cathode (positive charge) separated by an electrolyte. The electrolyte transports ions between the electrodes. The total power can be increased by connecting several of these cells together to build a stack. Electrical current flows from one cell to the next via busbars or electrical connections. In the process, both the reaction products (water) and the excess hydrogen are removed from the system.

Hydrogen stacks are used in a wide variety of applications, including electric vehicles, stationary power, portable devices and more. They offer an efficient and clean way to generate electrical energy because hydrogen fuel produces no harmful emissions, only water vapor.

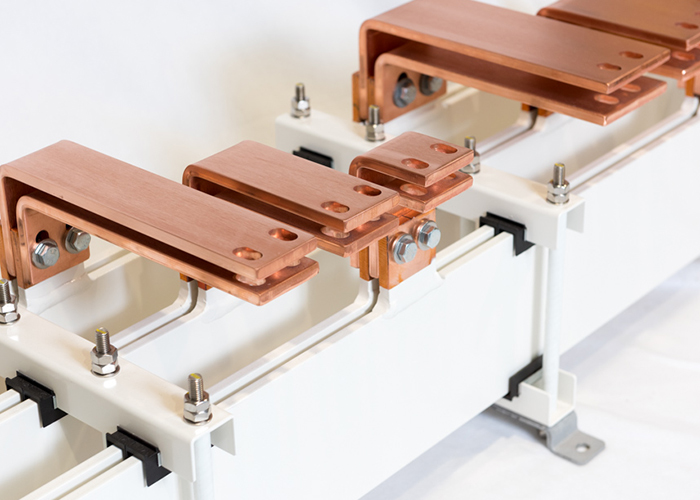

The main function of the busbars is to conduct the current from one fuel cell to the next. This increases the overall performance of the stack. By using busbars, the electrical current is evenly distributed throughout the stack. The result is an efficient use of the generated electricity and the guarantee of a uniform power in all cells.

The busbars are located at the ends of the individual cells in the stack. One busbar is connected to the positive terminal of one cell, the other to the negative terminal of the next. We offer both solid and flexible busbars. We will be happy to advise you on the selection of the right material.

It is important to note that the exact application and design of busbars in hydrogen stacks depends on several factors. These include the specific design of the stack and the requirements of the application. We will be happy to advise you.

We engineer your Industry-Busbars

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

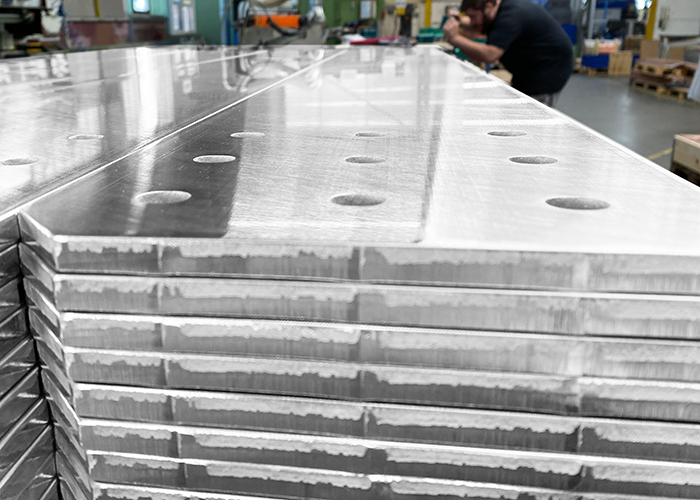

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFor experts by experts

At EMS, we have many years of experience in the engineering, manufacturing, and installation of innovative busbar systems.

“Together with you as a strategic partner, we engineer forward-looking solutions for tomorrow’s industry!”

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

online-Meeting

Book your consultation appointment now:

Michael Stein

P: +49 6307 9116 699

M: +49 151 153 019 60

E: mstein@ems-power.com

Would you like a customized offer? I look forward to receiving your request:

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.