Laminated & Insulated Flexible Busbars Isoflexx®

- Flexible lamellae

- Resistant insulations

- High quality

- Standards are UL approved

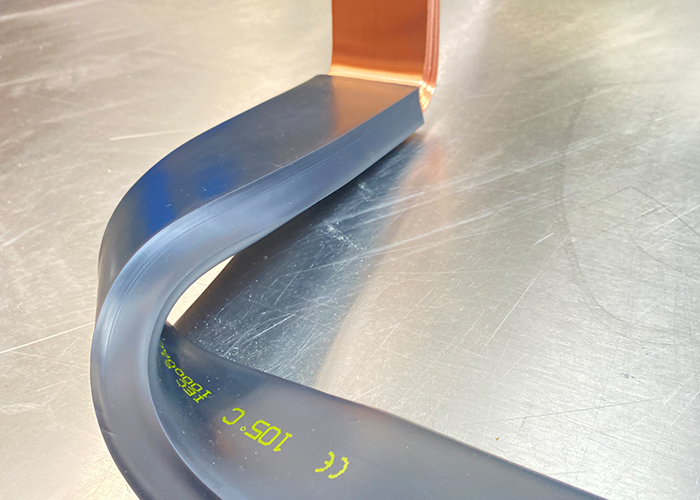

Whether as a moving component in solid busbar systems, for connection to generators, transformers, switchgear and switching devices, as a supply line to machine switches and immersion baths, or as a riser in switchgear – Laminated Insulated Flexible Busbars Isoflexx® are innovative electrical connections for your low-voltage installation.

The loose lamellea lying in the insulation offer excellent flexibility and are also suitable for drilling or punching.

Flexible Busbar Lamellea & Connections

Conductor material Laminated Isoflexx®

We manufacture Laminated Insulated Flexible Busbars Isoflexx® in cross-sections from 21.6 to 1200 mm². The copper lamellae are manufactured from highly conductive Cu-ETP.

- Electrical conductivity 58 MS/m

- Tensile strength 200 MPa [R200].

- Lamella thicknesses from 0.5 mm to 1.0 mm

- Cu-ETP bare or Cu-ETP tinned (more corrosion resistant)

Isoflexx® Connections

In the manufacturing of technically advanced connectors made of different materials, EMS has rich experience.

Press welded connections (bare copper only) on one or both sides, have excellent conductivity due to their molecular bonding. The connection surfaces can be drilled, milled and bent.

The EMS Group is certified according to

DIN EN ISO 9001:2015

Resistant Insulated Flexible Busbars Isoflexx®

Our Isoflexx® Classic & Premium (105-190°C) allow higher temperatures than PVC or XLPE cables (70-90°C). As a result, a significantly higher current carrying capacity can be achieved. Isoflexx® insulation is resistant and has reinforced edges to withstand high operating voltages. The homogeneous, stress-free insulation prevents cracking at edges. Isoflexx® busbar insulations are available in various colors and comply with the RoHS directive.

SPS Standard Produkte Schwanenmühle GmbH offers standard Isoflexx® from stock. Please visit our SPS website or our SPS store!

| Product | Isoflexx® Classic | Isoflexx® Premium | Isoflexx® Rail |

|---|---|---|---|

| Colors insulation | Black, Blue, Green+Yellow | Grey | Black |

| Thickness [mm] | ≥ 1 | ≥ 2 | ≥ 1,5 |

| Dielectric strength | 20 kV/mm | 16 kV/mm | 21 kV/mm |

| Elongation | 370 % | 180 % | 550 % |

| Operating temperature | -40 °C / +105 °C | -40 °C / +190 °C | -40 °C / +105 °C |

| Operating voltage | 1000 VAC/1500 VDC (UL 600 VAC/750 VDC) | 1000 VAC/1500 VDC (UL 600 VAC/750 VDC) | 1000 VAC/1500 VDC |

| Flammability | UL 94 V0 | UL 94 V0 | UL 94 V0 |

| Glow wire test | 960°C | 960°C | 960°C |

| Material | Special PVC, Self-extinguishing, Migration resistant, Compatible with various construction materials | Silicone, Halogen free, Self-extinguishing | Thermoplastic elastomer (TPE), Halogen free, Insulation fulfills flame protection requirements for railroad applications |

| Approvals | UL 758, UL 508 | UL 508 | UL 94 V-0 (1.5 mm), DIN EN 45545-2 R22 HL2, DIN EN 45545-2 R23 HL3 |

Isoflexx® Classic

The special PVC insulation of Isoflexx® Classic is naturally self-extinguishing and is often used in industrial applications. The plasticizer is migration resistant and compatible with construction materials such as polycarbonate and polymethyl methacrylate.

Approvals of Standard Isoflexx® Classic by SPS

UL 758, UL 508

Standards

RoHS, CE, REACH, ICE 61439-1

Isoflexx® Premium

The halogen-free silicone insulation of Isoflexx® Premium is self-extinguishing, produces only a very small amount of toxic smoke in case of fire, and is therefore often used in public buildings. The insulation hose is a homogeneous profile which is pulled over the conductor material.

Approvals of Standard Isoflexx® Premium by SPS

UL 508

Standards

RoHS, CE, REACH, ICE 61439–1

Isoflexx® Rail

Isoflexx® Rail’s halogen-free TPE insulation generates only a very small amount of toxic smoke in the event of fire and can therefore also be used in public facilities. Isoflexx® Rail insulation also meets the flame retardant requirements for rail applications – for greater safety for people and railroads.

Approvals of the Standard-Isoflexx® Rail by SPS

DIN EN 45545-2/R22/23HL3 (Isolation)

Standards

RoHS, CE, REACH, ICE 61439–1

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ Variable lengths from 250 to 3000 mm

+ Perforations of the connections

+ Twisting of both connections by 90°

+ Bends over the wide side

+ Folds over the high edge

+ Personalizations

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Isoflexx® current carrying capacity

For Insulated Flexible Busbars Isoflexx®, the current carrying capacity applies according to the following table, determined according to IEC or UL standard:

Typenbez. / Type Querschnitt / Cross section [mm²] Anzahl Lamellen / Number lamellas Breite Lamellen / Width lamellas [mm] Dicke Lamellen / Thickness lamellas [mm] Farbe Isolierung / color insulation Strombelastung/ Current rating [A]* 65°C Strombelastung / Current rating [A]* 85°C Strombelastung / Current rating [A]* 105°C

IFX-C- 2 x 32 x 1

64

2

32

1,00

⚫️

290

384

456

IFX-C- 2 x 24 x 1

48

2

24

1,00

⚫️

242

320

380

IFX-C- 2 x 20 x 1

40

2

20

1,00

⚫️

208

275

326

IFX-C- 3 x 9 x 0,8

21

3

9

0,80

⚫️

121

160

190

IFX-C- 3 x 32 x 1

96

3

32

1,00

⚫️

361

477

567

IFX-C- 3 x 24 x 1

72

3

24

1,00

⚫️

303

400

475

IFX-C- 3 x 20 x 1

60

3

20

1,00

⚫️

261

345

410

IFX-C- 4 x 32 x 1

128

4

32

1,00

⚫️

421

556

661

IFX-C- 4 x 24 x 1

96

4

24

1,00

⚫️

348

460

546

IFX-C- 4 x 20 x 1

80

4

20

1,00

⚫️

303

400

475

IFX-C- 4 x 16 x 0,8

49

4

16

0,80

⚫️

227

300

356

IFX-C- 5 x 80 x 1

400

5

80

1,00

⚫️

1.022

1.350

1.605

IFX-C- 5 x 63 x 1

315

5

63

1,00

⚫️

832

1.099

1.306

IFX-C- 5 x 50 x 1

250

5

50

1,00

⚫️

702

927

1.102

IFX-C- 5 x 40 x 1

200

5

40

1,00

⚫️

577

762

906

IFX-C- 5 x 32 x 1

160

5

32

1,00

⚫️

480

634

753

IFX-C- 5 x 24 x 1

120

5

24

1,00

⚫️

405

535

636

IFX-C- 5 x 20 x 1

100

5

20

1,00

⚫️

321

424

504

IFX-C- 5 x 100 x 1

500

5

100

1,00

⚫️

1.215

1.604

1.907

IFX-C- 6 x 9 x 0,8

43

6

9

0,80

⚫️

189

250

297

IFX-C- 6 x 80 x 1

480

6

80

1,00

⚫️

1.105

1.460

1.735

IFX-C- 6 x 63 x 1

378

6

63

1,00

⚫️

949

1.253

1.489

IFX-C- 6 x 50 x 1

300

6

50

1,00

⚫️

772

1.020

1.212

IFX-C- 6 x 40 x 1

240

6

40

1,00

⚫️

632

835

992

IFX-C- 6 x 32 x 1

192

6

32

1,00

⚫️

530

700

832

IFX-C- 6 x 24 x 1

144

6

24

1,00

⚫️

439

580

689

IFX-C- 6 x 20 x 1

120

6

20

1,00

⚫️

357

472

561

IFX-C- 6 x 16 x 0,8

74

6

16

0,80

⚫️

287

380

451

IFX-C- 6 x 100 x 1

600

6

100

1,00

⚫️

1.257

1.660

1.973

IFX-C- 8 x 80 x 1

640

8

80

1,00

⚫️

1.280

1.690

2.009

IFX-C- 8 x 63 x 1

504

8

63

1,00

⚫️

1.030

1.361

1.618

IFX-C- 8 x 50 x 1

400

8

50

1,00

⚫️

897

1.185

1.408

IFX-C- 8 x 40 x 1

320

8

40

1,00

⚫️

744

983

1.168

IFX-C- 8 x 32 x 1

256

8

32

1,00

⚫️

627

829

985

IFX-C- 8 x 24 x 1

192

8

24

1,00

⚫️

530

700

832

IFX-C- 8 x 100 x 1

800

8

100

1,00

⚫️

1.461

1.930

2.294

IFX-C- 10 x 80 x 1

800

10

80

1,00

⚫️

1.416

1.870

2.223

IFX-C- 10 x 63 x 1

630

10

63

1,00

⚫️

1.188

1.569

1.865

IFX-C- 10 x 50 x 1

500

10

50

1,00

⚫️

1.027

1.357

1.613

IFX-C- 10 x 40 x 1

400

10

40

1,00

⚫️

856

1.131

1.344

IFX-C- 10 x 32 x 1

320

10

32

1,00

⚫️

726

959

1.140

IFX-C- 10 x 24 x 1

240

10

24

1,00

⚫️

606

800

951

IFX-C- 10 x 20 x 1

200

10

20

1,00

⚫️

500

661

785

IFX-C- 10 x 16 x 0,8

124

10

16

0,80

⚫️

348

460

546

IFX-C- 10 x 100 x 1

1.000

10

100

1,00

⚫️

1.631

2.154

2.561

IFX-C- 11 x 21 x 1

231

11

21

1,00

⚫️

567

749

890

IFX-C- 12 x 100 x 1

1.200

12

100

1,00

⚫️

1.724

2.276

2.706

Farbe Isolierung / color insulation

Typenbez. / Type Querschnitt / Cross section [mm²] Anzahl Lamellen / Number lamellas Breite Lamellen / Width lamellas [mm] Dicke Lamellen / Thickness lamellas [mm] Farbe Isolierung / color insulation [Cu-ETP blank/ bare] Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] Strombelastung/ Current rating [A]* 65°C Strombelastung/ Current rating [A]* 85°C Strombelastung/ Current rating [A]* 105°C

IFX-P- 5 x 50 x 1

250

5

50

1,00

Auf Anfrage / On request

Auf Anfrage / On request

702

927

1.102

IFX-P- 5 x 40 x 1

200

5

40

1,00

Auf Anfrage / On request

Auf Anfrage / On request

577

762

906

IFX-P- 5 x 32 x 1

160

5

32

1,00

Auf Anfrage / On request

Auf Anfrage / On request

480

634

753

IFX-P- 5 x 24 x 1

120

5

24

1,00

Auf Anfrage / On request

Auf Anfrage / On request

405

535

636

IFX-P- 5 x 20 x 1

100

5

20

1,00

Auf Anfrage / On request

Auf Anfrage / On request

321

424

504

IFX-P- 5 x 100 x 1

500

5

100

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.215

1.604

1.907

IFX-P- 12 x 100 x 1

1.200

12

100

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.724

2.276

2.706

IFX-P- 10 x 80 x 1

800

10

80

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.280

1.690

2.009

IFX-P- 10 x 63 x 1

630

10

63

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.030

1.361

1.618

IFX-P- 10 x 50 x 1

500

10

50

1,00

Auf Anfrage / On request

Auf Anfrage / On request

897

1.185

1.408

IFX-P- 10 x 40 x 1

400

10

40

1,00

Auf Anfrage / On request

Auf Anfrage / On request

856

1.131

1.344

IFX-P- 10 x 32 x 1

320

10

32

1,00

Auf Anfrage / On request

Auf Anfrage / On request

726

959

1.140

IFX-P- 10 x 24 x 1

240

10

24

1,00

Auf Anfrage / On request

Auf Anfrage / On request

606

800

951

IFX-P- 10 x 20 x 1

200

10

20

1,00

Auf Anfrage / On request

Auf Anfrage / On request

500

661

785

IFX-P- 10 x 120 x 1

1.200

10

120

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.780

2.350

2.794

IFX-P- 10 x 100 x 1

1.000

10

100

1,00

Auf Anfrage / On request

Auf Anfrage / On request

1.631

2.154

2.561

Farbe Isolierung / color insulation [Cu-ETP blank/ bare] Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned]

Typenbez. / Type Querschnitt / Cross section [mm²] Anzahl Lamellen / Number lamellas Breite Lamellen / Width lamellas [mm] Dicke Lamellen / Thickness lamellas [mm] Farbe Isolierung / color insulation [Cu-ETP blank/ bare] Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] Strombelastung/ Current rating [A]* 65°C Strombelastung / Current rating [A]* 85°C Strombelastung / Current rating [A]* 105°C

IFX-R- 5 x 20 x 1

100,00

5

20,00

1,00

Auf Anfrage / On request

⚫️

321

424

504

IFX-R- 5 x 24 x 1

120,00

5

24,00

1,00

Auf Anfrage / On request

⚫️

405

535

636

IFX-R- 5 x 32 x 1

160,00

5

32,00

1,00

Auf Anfrage / On request

⚫️

480

634

753

IFX-R- 10 x 24 x 1

240,00

10

24,00

1,00

Auf Anfrage / On request

⚫️

606

800

951

IFX-R- 10 x 32 x 1

320,00

10

32,00

1,00

Auf Anfrage / On request

⚫️

726

959

1.140

IFX-R- 10 x 40 x 1

400,00

10

40,00

1,00

Auf Anfrage / On request

⚫️

856

1.131

1.344

IFX-R- 10 x 50 x 1

500,00

10

50,00

1,00

Auf Anfrage / On request

⚫️

1.027

1.357

1.613

IFX-R- 6 x 16 x 0,8

74,40

6

16,00

0,80

Auf Anfrage / On request

⚫️

287

380

451

IFX-R- 6 x 15,5 x 0,8 (verzinnt)

74,40

6

15,50

0,80

Auf Anfrage / On request

⚫️

287

380

451

IFX-R- 6 x 9 x 0,8

43,20

6

9,00

0,80

Auf Anfrage / On request

⚫️

189

250

297

IFX-R- 10 x 16 x 0,8

124,00

10

16,00

0,80

Auf Anfrage / On request

⚫️

348

460

546

Farbe Isolierung / color insulation [Cu-ETP blank/ bare] Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned]

*Current load values: ambient temperature 35 °C, alternating current AC