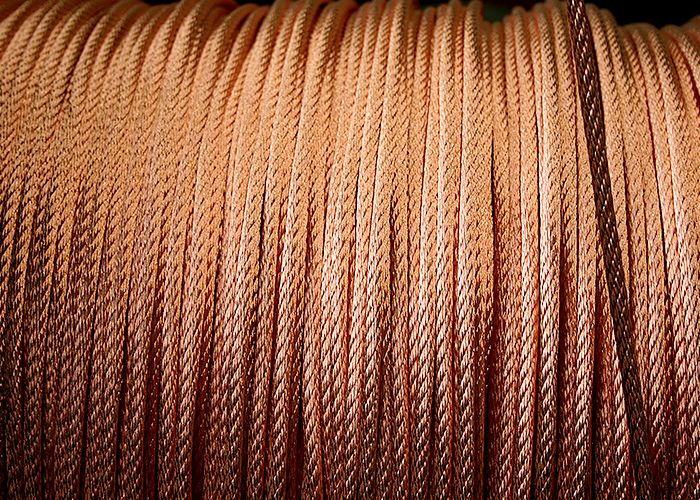

Braided flexible busbars as movable connectors

- High current transmission

- Allow shifts

- Absorb vibrations & strains

Braided Flexible Busbars (flat or round) are highly flexible high-current copper braid connectors and are used, for example, as moving elements in switchgear and equipment construction. Our Braided Flexible Busbars enable the transmission of high currents between components that are subject to vibration and compensate for three-dimensional movements. Round braids allow high flexibility in all directions of movement. EMS engineers and manufactures Braided Flexible Busbars in various customized dimensions. Please contact us!

Braided Flexible Busbars Conductor Material & Connections

Conductor Material Braided Flexible Busbars

The machine made flat or round braids consist of thin individual wires with thicknesses of 0.07-0.3 mm and can be made of the following materials:

- Cu-ETP1, bare or tinned

- Aluminum

- Stainless steel on request

EMS also manufactures Braided Flexible Busbars with surface finishes on request. Please contact us!

Connections Braided Flexible Busbars

Our Braided Flexible Busbars have solid terminations made from mechanically crimped sleeves or from cable lugs:

- Press-welded connections are welded directly without a sleeve using the pressure welding process. To avoid oxidation or tarnish, the pressure welding is done under water, for example.

- Tube-pressed connections made of copper, aluminum or stainless steel are pressed under high pressure in a calibration device (with a material filling ratio of more than 95 %).

- Terminations with standardized cable lugs are pressed onto round stranded wire.

EMS engineers and manufactures customized Braided Flexible Busbars in different terminations – contact us now!

The EMS Group is certified according to

DIN EN ISO 9001:2015

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!

Your customized Braided Flexible Busbars

Configure Braided Flexible Busbars correctly

EMS engineers and manufactures Braided Flexible Busbars with customized connections on request. Our Braided Flexible Busbars are manufactured according to DIN 46276.

Example description: LICU 120/40/60/220

Material: LICU for copper or LIAL for aluminum

Cross section: 120 mm²

Width: 40 mm

Connection length: 60 mm

Total length: 220 mm (when bent, correspondingly longer when stretched)

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit