Flexible Busbar Solutions for E-mobility

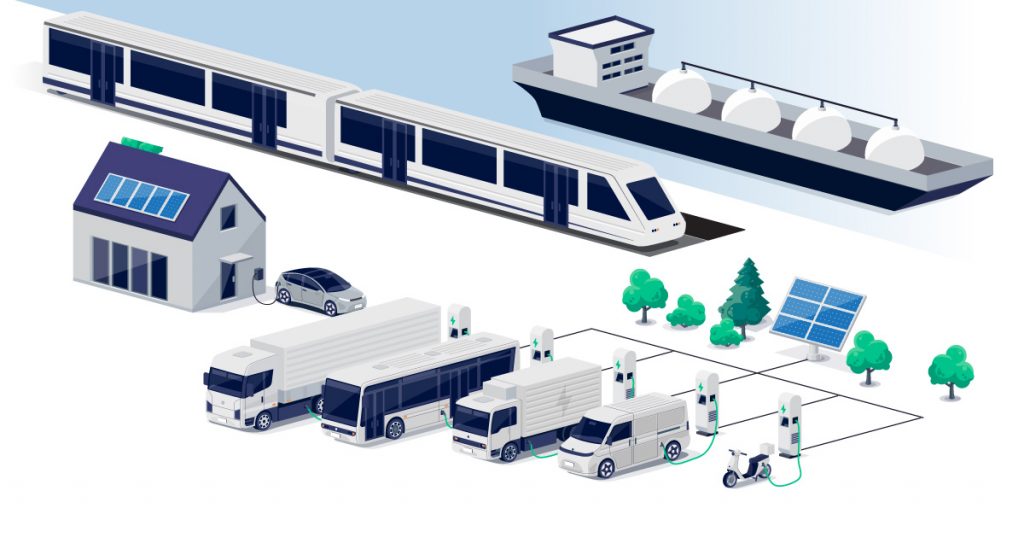

For us, E-mobility today means mobile applications of power transmission and grounding concepts. Our main areas of application are the engineering of busbar solutions for the marine, rail, off-highway, commercial vehicle and truck industries, from prototype production to small series. Here, the challenge consists primarily of the combination of weight, current carrying capacity, plating, insulation and installation space and the symbiotic integration into the Assembly units of our customers. By analyzing your installation situation and its environmental conditions, we work with you to develop the right components for your application, always made to measure.

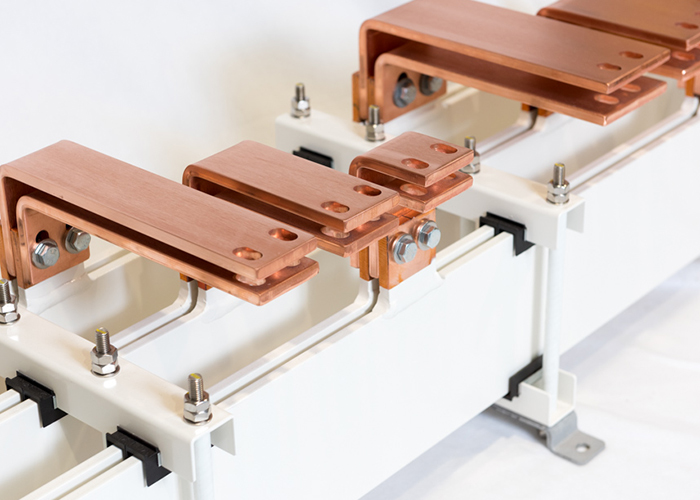

Mobile high current busbars

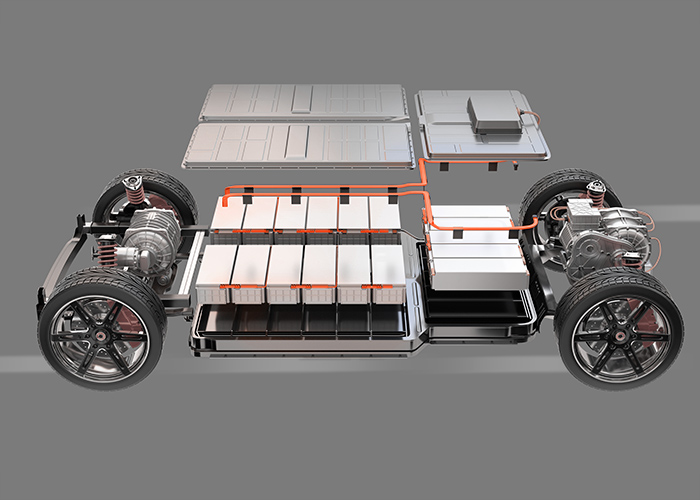

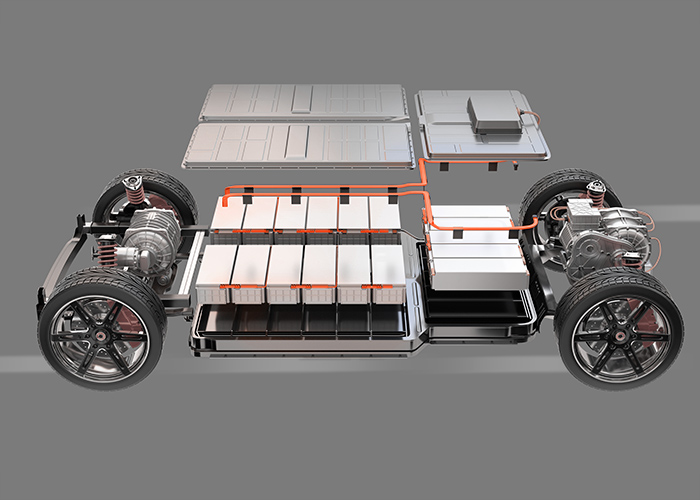

Flexible battery busbars for e-mobility

- Marine, Tail & Off-Highway

- Commercial vehicles like trucks, forklift & sweeper

- Fun sports equipment like surfboards

No matter which vehicle you are currently developing, we help you realize your applications with battery electric drive. In cooperation with our customers, we develop trend-setting solutions such as flexible expansion busbars, highly flexible stranded wires or assembly units for battery-electric mobility.

Energy transition with hydrogen mobility

- Hydrogen for automotive industry

- Hydrogen for rail & marine industry

Hydrogen mobility is a clear alternative for cutting CO₂ emissions. The hydrogen stored in the vehicle is converted into electricity by means of a fuel cell, which in turn drives the electric motor. The two major advantages over current e-vehicles are fast refueling and long ranges. Hydrogen-fed fuel cells are currently already being used in the car, truck, marine, and rail industries. Here, too, our components combine power transmission in the most efficient way. Contact us now!

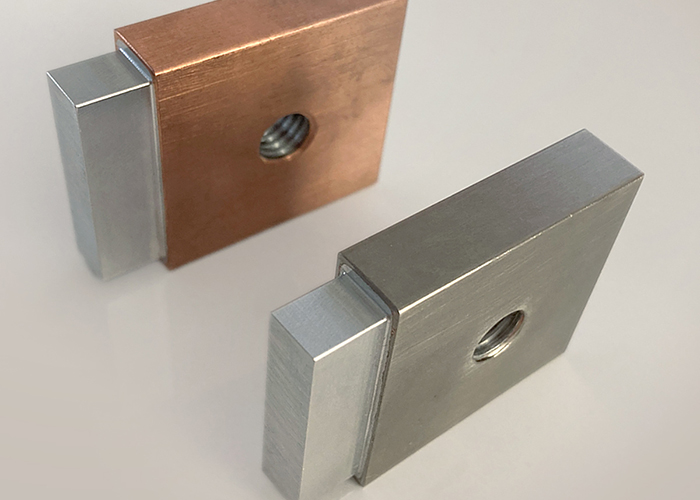

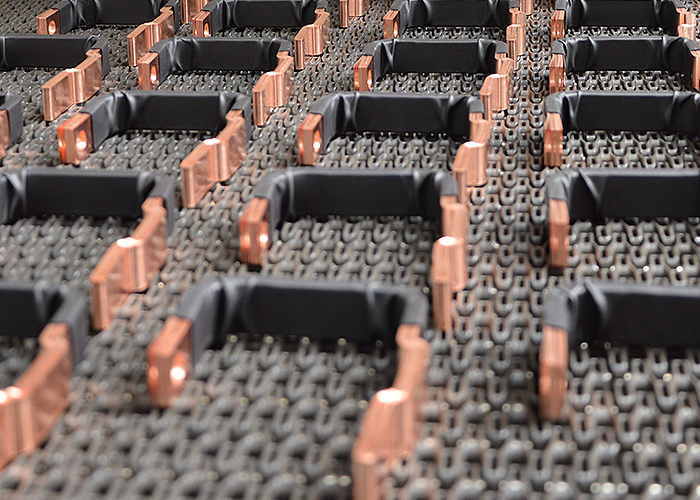

Grounding concepts for railroad technology

In railroad engineering, aluminum components such as car bodies and containers must be grounded in order to guarantee trouble-free operating current returns. The EMS grounding lugs serve as a connection piece for grounding cables to ground the aluminum components.

The special feature of our CoppAl® grounding lugs is their weld-resistant coating. This means that the EMS grounding lugs can be welded directly to the aluminum components to form a positive connection. Transition resistances can thus be permanently reduced. Our CoppAl® grounding lugs are made of composite material (CuAL or Cuponal) and optimally combine highly conductive copper with the low weight of aluminum.

Our solutions for your e-mobility

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBattery Busbars for E-mobility

At EMS, we have many years of experience in the development, manufacture and installation of innovative conductor rail systems.

Our expansion belts are used as expansion and vibration compensation in various vehicles. They are also used as flexible components for power transmission in machine parts, motors and switchgear.

‘Together with you as a strategic partner, we develop pioneering solutions for the mobility of tomorrow!’

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

online-Meeting

Book your consultation appointment now:

Udo Müller

P: +49 6307 9116 981

M: +49 152 283 172 49

E: umueller@ems-power.com

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.

You would like to receive an offer directly? Then simply use our form - we look forward to hearing from you!