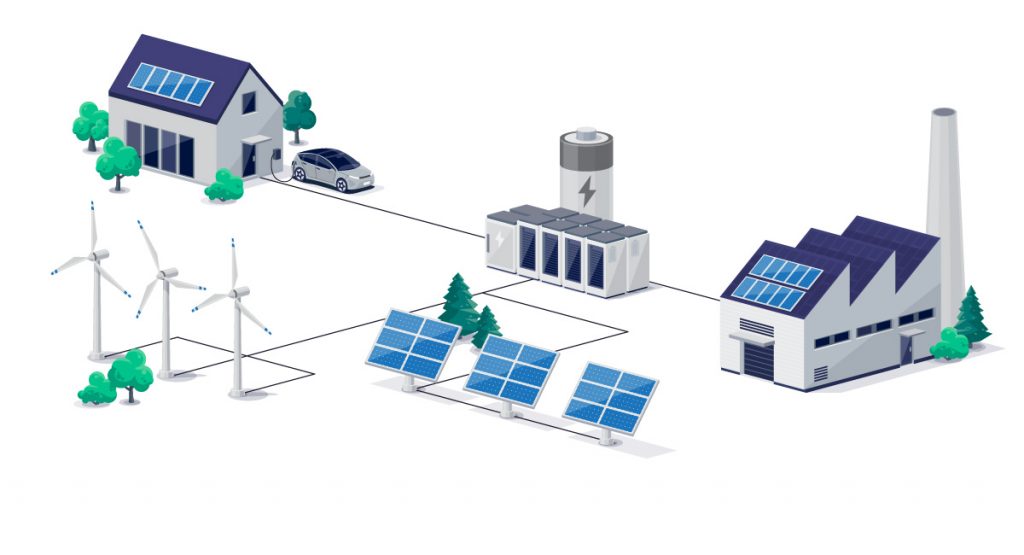

System solutions for renewable energies

Renewable energies include the wind, solar, photovoltaic, hydropower, biomass and geothermal industries. Our system solutions are used, among other things, as electrical conductors in generators, converters, transformers of wind turbines, as well as inverters for PV systems.

Solutions for renewable energies

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWhen everything turns around busbars...

… we also generate wind! Even if you don’t see our components at first glance, they are an integral part of wind turbines. With our busbars, we are actively shaping the energy transition and taking an important step towards a more sustainable future. In addition to wind power, our target markets also include other renewable energies such as the PV or hydrogen industry.

EMS is a member of APQP4Wind. The goal of APQP4Wind is to make the quality requirements process (APQP) and the product release process (PPAP) as clear as possible.

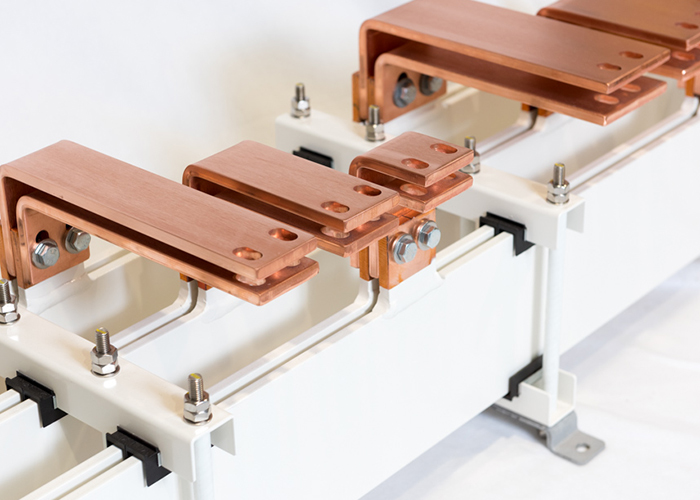

Proven system solutions in wind turbines

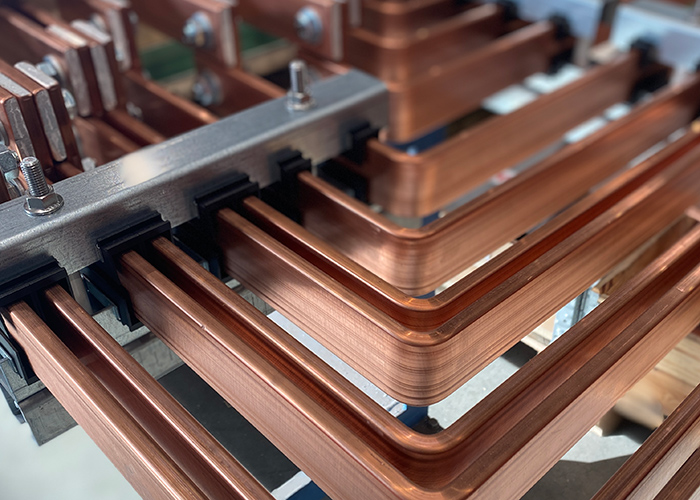

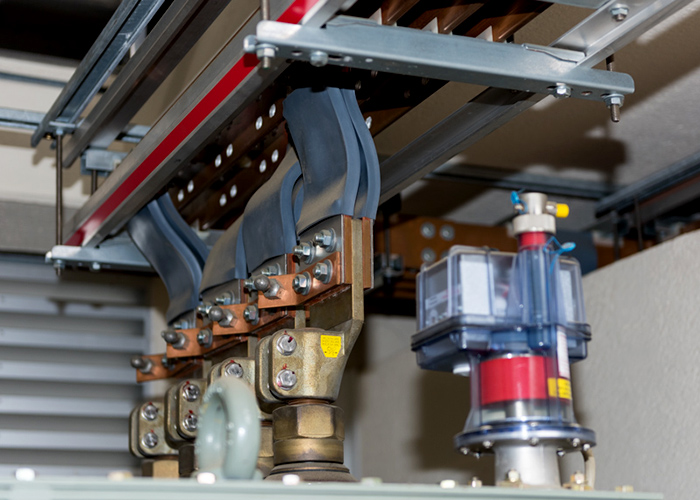

Our massive and flexible components can be installed in tight spaces, have low maintenance requirements and can transmit very high amounts of energy. Our proven systems of modular components are particularly suitable for generators, converters & transformers.

These systems have many advantages over cable solutions such as fast installation, current ratings up to 10,000 amps and more, exact coordination with other required products such as converters and transformers. In the case of inaccessible conditions, it is even possible to dispense with a corresponding housing.

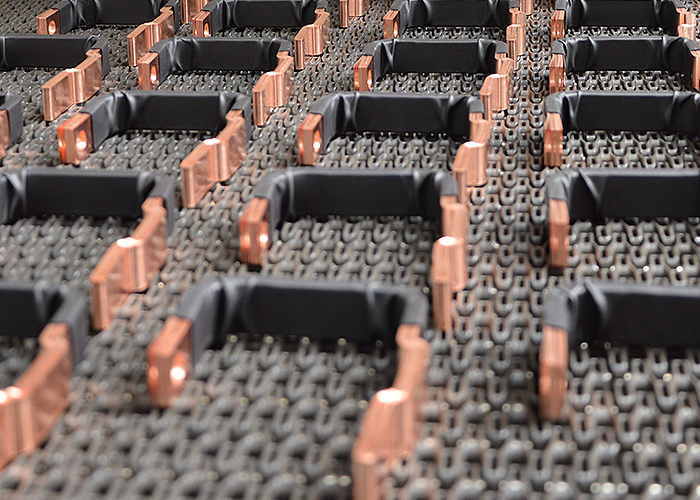

Copper components in photovoltaic inverters

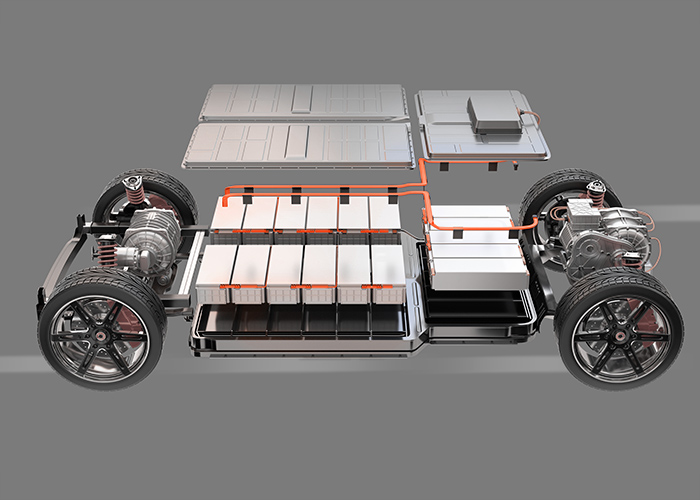

Photovoltaic inverters are a critical component in PV solar systems. While the PV modules are crucial for generating direct current (DC), photovoltaic inverters enable the conversion of this electrical energy into alternating current (AC).

Our copper components are used for electrical energy distribution in such photovoltaic inverters. Here, the cross-sections of the busbars and the operating temperature are relevant influencing variables. The current carrying capacity of a busbar always refers to the busbar itself and is one of the most important variables in the design of a copper busbar. Please contact us!

Assembly units for regenerative energies

- Partial or subassembly

- On site or ex works

We offer the production of subassemblies or complete Assembly unit solutions – pre-assembled ex works or at your site.

If required, our experienced technicians and assemblers will accompany you from engineering to and installation.

Our optimized capacity planning ensures that Assembly units are pre-assembled and delivered within the specified time.

Sustainable into the future

EMS engineers busbar systems with the lowest possible environmental impact. Thus, as standard, no painted housings or plastic-coated conductors are used, which cause additional burdens on the environment during production.

The use of pure materials, such as aluminum instead of epoxy-coated sheet steel, makes it easy to separate and recycle the busbars at a later date.

Solutions for your renewables

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

online-Meeting

Book your consultation appointment now:

Florian Müller

P: +49 6307 9116-178

M: +49 162 2036725

E: fmueller@ems-power.com

You would like to receive an offer directly? Contact us -

we look forward to hearing from you!

Discover our components

Whether you need solid busbars made of copper, aluminum or CoppAl®, flexible components or combined solutions – we manufacture everything from simple components to fully pre-assembled assemblies according to individual customer requirements.