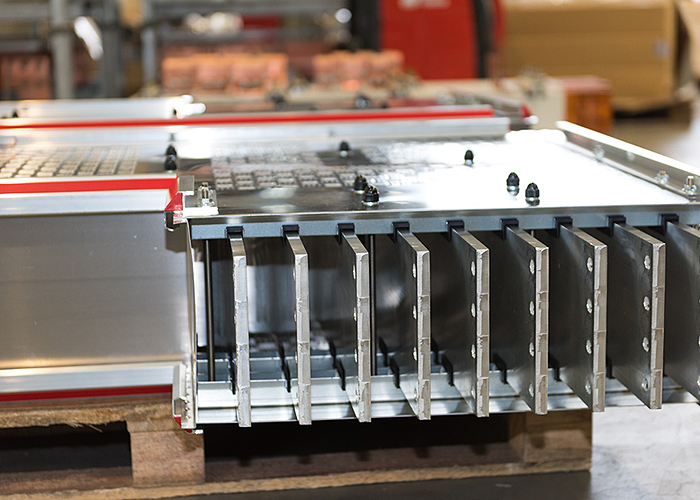

Customized aluminum busbars

- Weight relevant applications

- Cost-saving potential for material-intensive applications

- Connection from generator & transformer to switchgear

- Connection from rectifier to switchgear

- Potential equalization busbars

Aluminum with high purity has excellent electrical properties. For this reason, aluminum rails are used both as current conductors and for optimized heat transfer at contact surfaces. Pure aluminum produces a closed aluminum oxide layer (Al2O3) under given environmental conditions. This property makes aluminum very corrosion resistant to external influences. However, this oxide layer is not conductive. Therefore, aluminum busbars require thorough pretreatment and preservation.

The EMS Group is certified according to

DIN EN ISO 9001:2015

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBusbar manufacturing with know-how

Our well-coordinated production in multi-shift operation ensures that we can react flexibly and produce your components and assembly units in the desired quality.

In addition, we are able to produce single pieces, prototypes, small quantities, but also large busbars with expansive dimensions and in high quantities at consistently high quality.

The real challenge is not high quality per se – but consistently high quality – contact us now!

Conductor material aluminum

Aluminum semi-finished products & lightweight busbar

- Aluminium EN AW-6082

- Aluminium EN AW-6060

Aluminum busbars are the lightweight alternative to copper busbars. Aluminum busbars have the advantage over copper that they are much lighter. The installation and also the handling of aluminum busbars is very easy due to the low weight. However, a low density also means that the cross-section, for the same amount of current, must be selected significantly larger compared to copper.The silvery light metal is ideally suited for all non-cutting manufacturing processes. Aluminum corrodes within a short time. For this reason, thorough pretreatment is important!

For the individual design of your busbars, use our engineering know-how – we look forward to hearing from you!

Current carrying capacity aluminum busbars

Typenbez. / Type Breite / Width [mm] Dicke / Thickness [mm] Länge / Length [mm] Querschnitt / Cross-section [mm²] Gewicht / Weight [kg/3000mm] Scharfe Kanten / Sharp edges [SH] Gerundete Kanten / Rounded edges [RD] Strombelastung/ Current rating [A]* 65°C Art.-Nr.

SCAL82 30x10x3000

30

10

3.000

300

2,43

✓

–

368

210.102

SCAL82 40x10x3000

40

10

3.000

400

3,24

✓

–

461

210.103

SCAL82 50x10x3000

50

10

3.000

500

4,05

✓

–

552

210.104

SCAL82 60x10x3000

60

10

3.000

600

4,86

✓

–

641

210.105

SCAL82 80x10x3000

80

10

3.000

800

6,48

✓

–

814

210.106

SCAL82 100x10x3000

100

10

3.000

1.000

8,10

✓

–

985

210.107

Strombelastung/ Current rating [A]* 65°C

Typenbez. / Type Breite / Width [mm] Dicke / Thickness [mm] Länge / Length [mm] Querschnitt / Cross-section [mm²] Gewicht / Weight [kg/6000mm] Strombelastung/ Current rating [A]* 65°C Scharfe Kanten / Sharp edges [SH] Gerundete Kanten / Rounded edges [RD] Art.-Nr.

SCAL60 30x5x6000

30

5

6.000

150

2,43

273

✓

–

210.072

SCAL60 50x5x6000

50

5

6.000

250

4,05

421

✓

–

210.070

SCAL60 60x5x6000

60

5

6.000

300

4,86

493

✓

–

210.071

SCAL60 80x5x6000

80

5

6.000

400

6,48

637

✓

–

210.101

SCAL60 30x10x6000

30

10

6.000

300

4,86

412

✓

–

210.055

SCAL60 40x10x6000

40

10

6.000

400

6,48

516

✓

–

210.008

SCAL60 50x10x6000

50

10

6.000

500

8,10

618

✓

–

210.009

SCAL60 60x10x6000

60

10

6.000

600

9,72

717

✓

–

210.024

SCAL60 80x10x6000

80

10

6.000

800

12,96

910

✓

–

210.003

SCAL60 100x10x6000

100

10

6.000

1.000

16,20

1.102

✓

–

210.010

SCAL60 120x10x6000

120

10

6.000

1.200

19,44

1.288

✓

–

210.011

SCAL60 140x10x6000

140

10

6.000

1.400

22,68

1.443

✓

–

210.033

SCAL60 160x10x6000

160

10

6.000

1.600

25,92

1.649

✓

–

210.016

SCAL60 200x10x6000

200

10

6.000

2.000

32,40

2.001

✓

–

210.030

SCAL60 250x10x6000

250

10

6.000

2.500

40,50

2.377

✓

–

210.018

Strombelastung/ Current rating [A]* 65°C

* Current load values: Ambient temperature 35 °C, AC current AC.

Heating of the busbar depending on: Current intensity, ambient temperature, heat dissipation, type of routing, installation, application Multiplication factor 1.72 when using 2 rails, multiplication factor 2.25 when using 3 rails in parallel arrangement.

Certified Specialist Welding Company

EMS Elektro Metall Schwanenmühle GmbH is a certified welding company in accordance with DIN EN ISO 3834 T3. Our joining and soldering techniques are an important core competence for the manufacturing of our components and busbar system solutions.

In addition to traditional welding techniques, we also offer various special processes on request — please contact us for more information!

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Customized manufacturing

+ Processing standard DIN EN 13601

+ Connecting pieces in welding systems

+ Individual perforations

+ Bending

+ Deburring

+ Punching

+ Sawing

+ Soldering

+ Personalizations

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit