Hydrogen Power Busbar Solutions

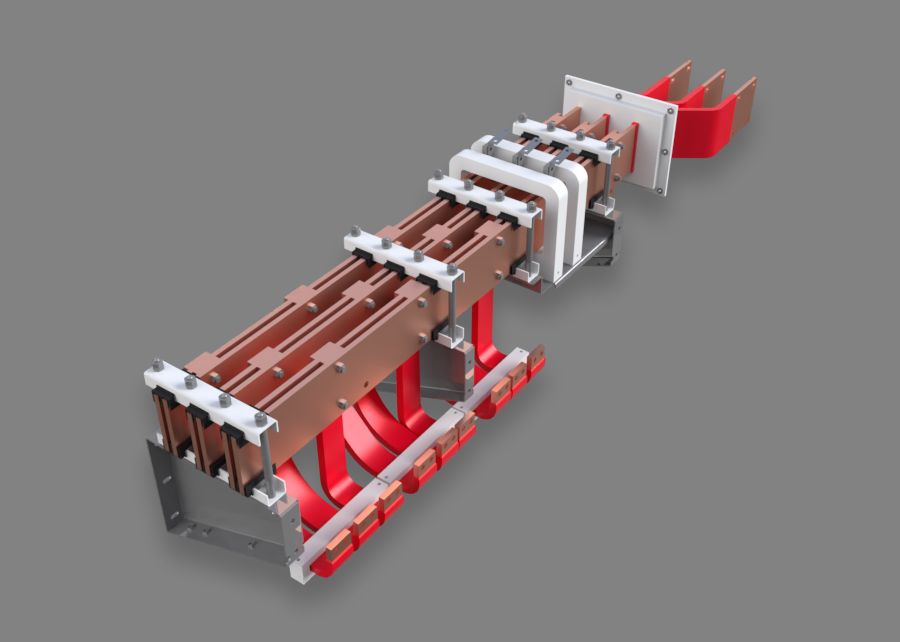

Many experts see green hydrogen as the energy source of the future for industry, heat supply and mobility. This is because green hydrogen can minimise CO₂ emissions and help to replace fossil fuels. The hydrogen electrolysis required for this is a process in which water (H₂O) is split into hydrogen (H₂) and oxygen (O₂). An electric current is passed through the water for this purpose. All processes require a reliable and stable power supply before, during and after the electrolysis of hydrogen. Our busbar solutions are an efficient method of transmitting electrical energy and provide an important, reliable and flexible energy supply for all stages of the electrolysis process. Our solutions are also used in the renewable energy sector, such as in solar power plants, wind farms or hydroelectric power plants.

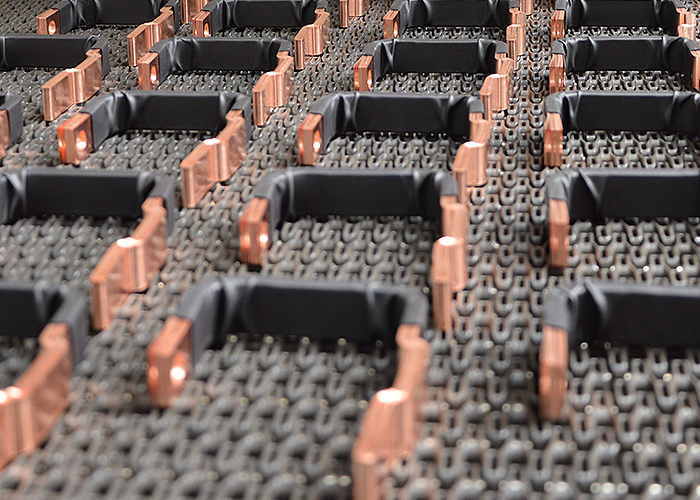

PEM electrolysis is an innovative technology with a short reaction time, high current density and flexibility that is already being used on an industrial scale. The advantages of PEM electrolysis are its dynamic reactivity, short cold start times and the ability to be coupled with fluctuating power sources.

The AEL is characterized by low investment costs, high long-term stability and the virtual absence of critical raw materials, but requires management of the alkaline electrolyte.

High-temperature electrolysis enables water splitting at over 100 °C with lower specific energy requirements than other electrolysis processes.

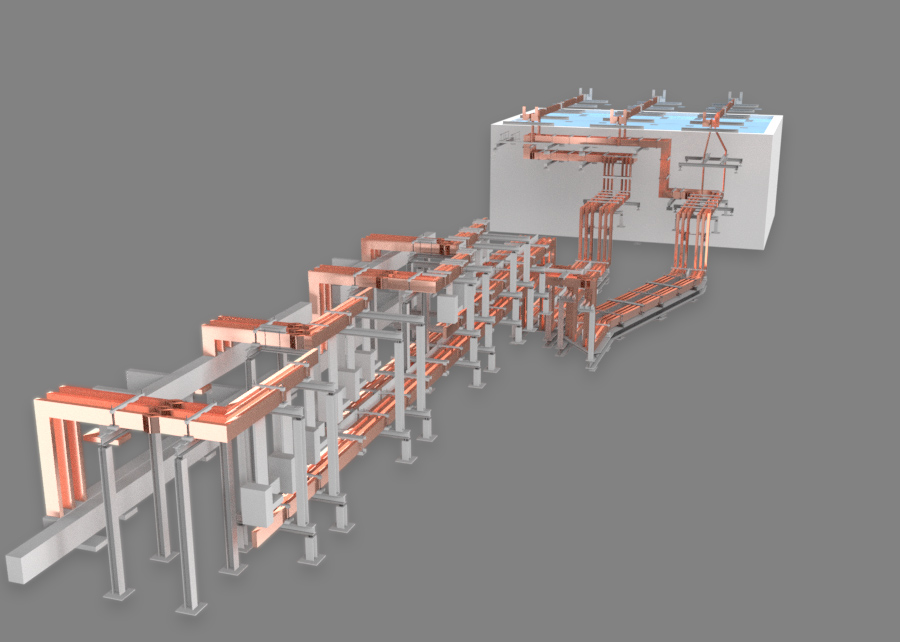

Power Busbars for your Hydrogen Systems

Precise & reliable energy supply

Electrical power is distributed precisely and efficiently with our busbar solutions. In plants for the production of hydrogen, especially in electrolysis, electrical energy is required for the splitting of water into hydrogen and oxygen. By using our busbar system solutions, the energy can be channelled precisely to where it is needed. This reduces energy losses.

When planning and designing busbar solutions, our developers pay particular attention to operational safety. Possible damage caused by short circuits is thus minimised.

Reducing Energy Losses

Compared to conventional methods of energy transmission, in which energy is transported over long distances using cables, high-quality busbar systems significantly reduce energy losses. The result is an improvement in the overall efficiency of energy transmission.

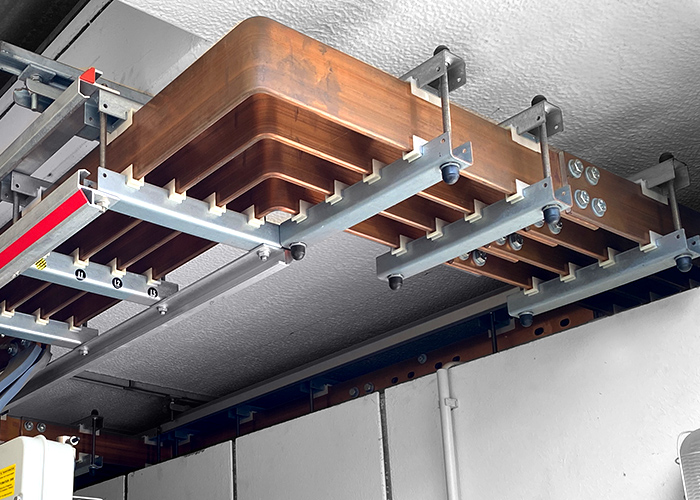

Flexible Busbar Systems

Our busbar components enable a more flexible and efficient power supply, as these systems can be more easily adapted to different requirements. This is particularly important in hydrogen production plants, where the power supply fluctuates according to demand.

Scalability of the System Solutions

Our busbar systems are used for the efficient and safe distribution of electrical power in a building or system. The additional use of assemblies makes it easier to de-energize and maintain individual sections without having to interrupt the entire power supply. Scalability of the power supply is therefore possible at any time. With our high-quality system solutions, electrical components can also be organized and protected in a spacesaving manner without the need for major changes to the infrastructure.

Efficient Power Busbars for Hydrogen Systems

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

We have the solution

FAQs: Power Busbars for Hydrogen

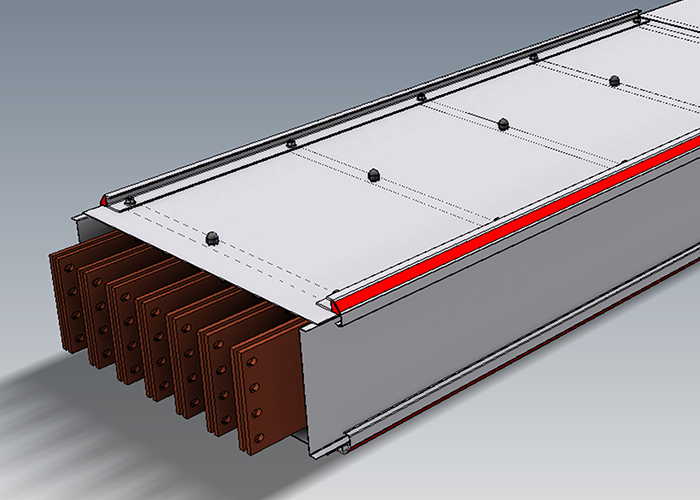

We specialize in complete busbar distribution systems between transformers, rectifiers and electrolysers, especially for hydrogen systems. Under the Vision®Electric brand, we primarily manufacture customized busbar systems in the range of 1,200 to 300,000 amperes especially for the harsh environment of the hydrogen industry according to your specifications.

Our experienced EMS designers ensure tailor-made results from analysis to engineering. Our project and production management also ensures that all components meet the defined requirements. On request, we can also take care of the assembly and shipment of your busbar systems.

At EMS, we have been developing, manufacturing and installing innovative busbar solutions for over 30 years. We would be happy to advise you – contact us!

In harsh and industrial environments, there are several ways to use busbars permanently and safely:

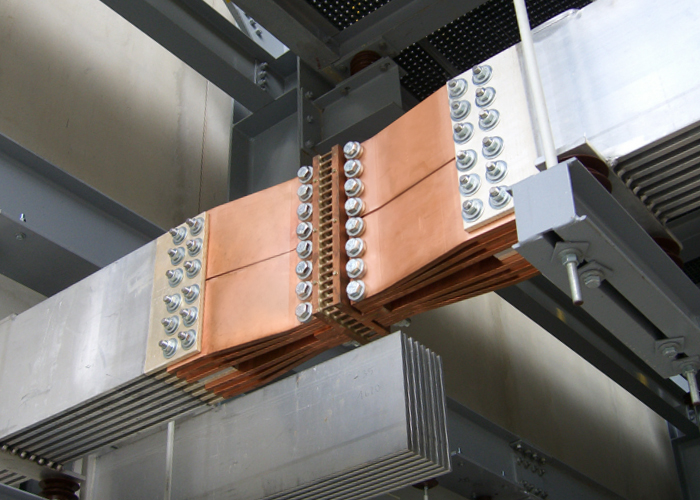

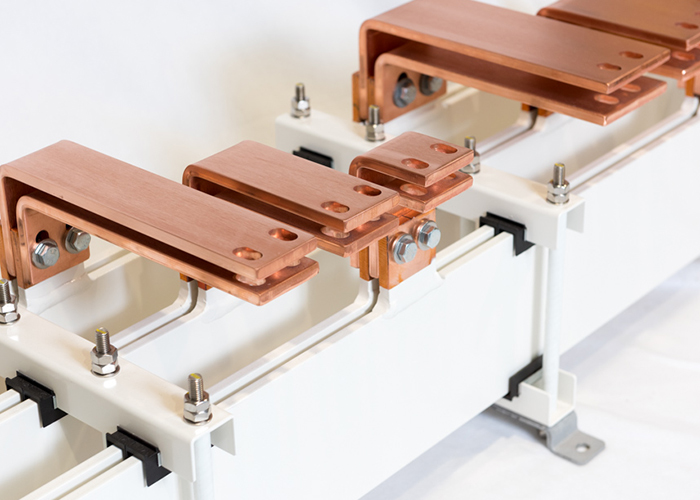

- To keep the voltage drop as low as possible, we only use highly conductive pure copper Cu-ETP (E-Cu), Cu-HCP or OF-Cu. Even if copper busbars oxidize over time, they remain conductive, but more energy is then required to conduct the current across the contact surface. For this reason, we offer various special coatings for additional insulating or conductive properties.

- Aluminum busbars are significantly lighter than copper busbars and can reduce costs. Pure aluminum forms a closed aluminum oxide layer (Al2O3) under the given environmental conditions. This property makes aluminum highly resistant to corrosion from external influences.

- Our tip: CoppAl® is a composite material that is used as an electrical connection in control cabinets, switchgear, and distribution boards. CoppAl® busbars are a more economical alternative to copper busbars with the same current-carrying capacity.

We are constantly looking for ways to improve energy efficiency in order to meet the growing demand. The use of busbar systems is the solution in many cases. This is because busbars can be used to transmit any type of electricity from any type of grid. Not only do they reduce system costs and improve reliability, they also increase capacity, avoid wiring errors and reduce inductance. Compared to other wiring methods, multi-layer busbars, for example, offer better structural integrity.

In addition, the physical structure of a busbar is an advantage in itself. Not only does it offer unique mechanical design features, but also an optimal surface to cross-section ratio that allows for more efficient heat dissipation.

online-Meeting

Book your consultation appointment now:

Michael Stein

P: +49 6307 9116-699

M: +49 151 153 019 60

E: mstein@ems-power.com

Sorry this appointment type isn't available, please check back later

Our service

Consulting

+ Individual offer

+ Detailed measurement

+ Guarantees

+ Contract conditions

+ Cost optimization

+ PPAP production release procedure

+ APQP guidelines

+ Audits

Engineering

+ Project management

+ Technical engineering

+ Cross-section design

+ Magnetic field calculation

+ 3D layout creation

+ Feasibility check

Customized manufacturing

+ Fabrication & Manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assemblies

+ Further processing

+ Personalizations

Logistics

+ Worldwide shipping

+ High quality packing

+ Upon request according to specification

+ Reliable & just-in-time

+ Dynamic capacity adjustment

Installation

+ Pre-assembly ex works

+ On-site installation

+ Supervision

After Sales

+ Maintenance

+ Spare parts requirement

+ Retro-fit

EMS core competencies

Power from a single source

Reliability, quality and sustainability are our claim. As a strategic partner we are the first choice for our hydrogen customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!