Power supply for challenging environments

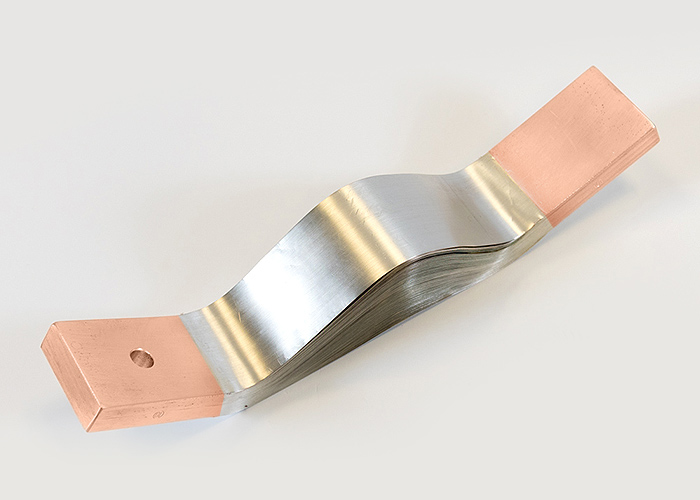

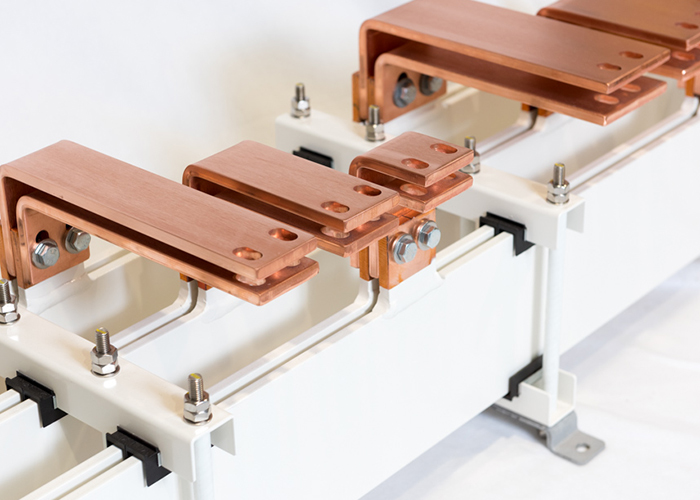

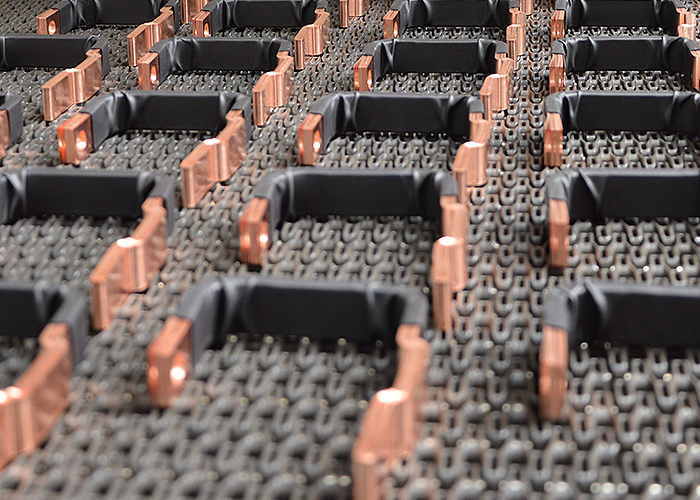

Flexible busbars are electrical conductors that offer individual connection options for safe current flow. Our flexible busbars are made from highly conductive materials such as copper lamellae or copper braiding and are available in customer-specific cross-sections.

Unlike solid busbars, flexible busbars are easier to install in confined spaces and around corners, making them a space-saving and reliable solution for power distribution in industrial applications. They also offer greater safety, as they are generally wear-, abrasion-, and fire-resistant.

Simplified power distribution with flexible busbars

Benefits of flexible busbars

Flexible busbars offer several advantages in terms of optimizing available space and improving safety in power distribution systems. First, their flexible design allows for easy installation in confined spaces, reducing the need for additional components and minimizing the overall size of the system.

In addition, flexible busbars are made of conductive materials that are wear-, abrasion-, and fire-resistant. This minimizes the risk of electrical fires, short circuits, and other hazards, providing a higher level of safety for employees and equipment.

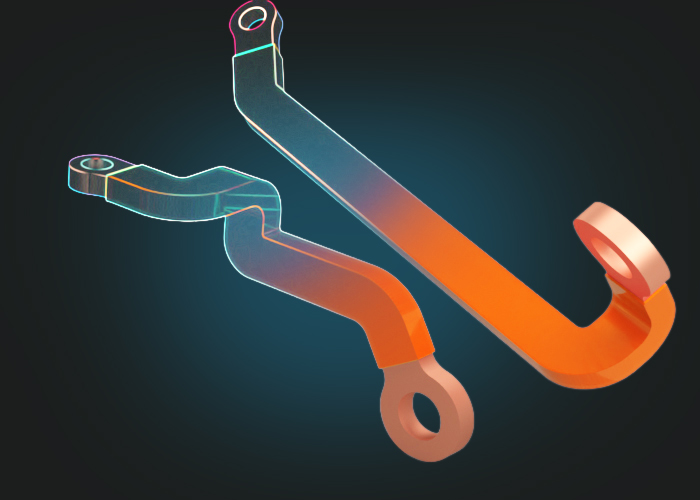

Highly flexible busbars from EMS

The three most common highly flexible busbars are Braided Flexible Busbars, Ultraflexx®, and Earth Braids.

Although they are all made of individual wires, there are significant differences in material, cross-sections, connections, insulation, and thus areas of application.

In addition to the standard range from SPS, we also engineer customized flexible busbars – we would be happy to advise you!

Flexible application options

Power supply: Used in electrical transmission grids to transfer electricity from a source to a consumer.

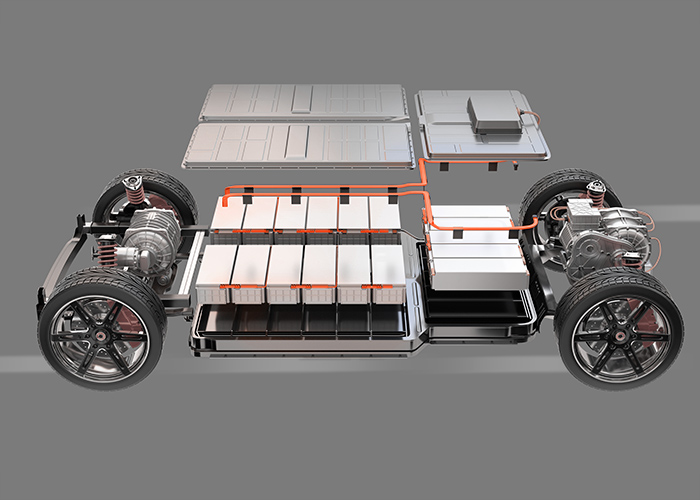

E-mobility: Used to supply power to electric motors and other electrical components in motor vehicles, ships, boats, railways, and aviation.

Renewable energies: Used in photovoltaic systems, hydroelectric power plants, and geothermal power plants to distribute the electricity generated, and in wind turbines to transmit the electricity generated from the rotors to the power distribution system.

Switchgear: Used in electrical systems to distribute electricity and monitor electrical systems.

FAQ's

Frequently asked questions about flexible busbars

Flexible busbars are electrical conductors that have a flexible and malleable structure. They are used in electrical systems to enable safe and easy transmission of electricity, especially in hard-to-reach places or when moving equipment or machinery.

Flexible busbars are usually attached to machines, devices, or walls using clamps or screws. They can be mounted in straight or curved shapes, depending on requirements.

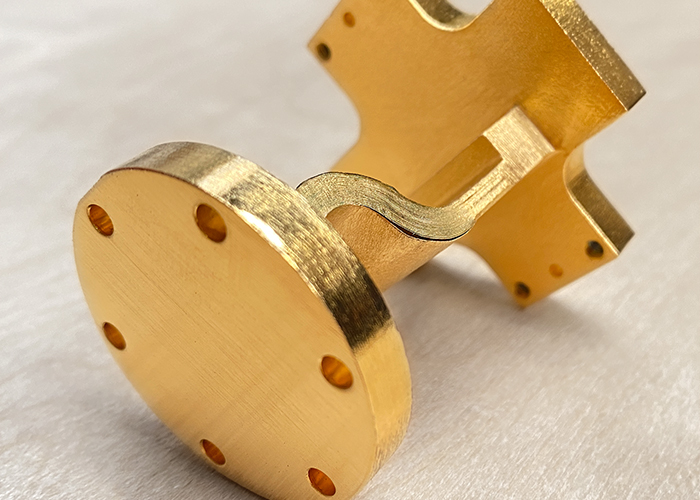

EMS manufactures and engineers flexible busbars made of lamellas such as:

And highly flexible busbars made of braided round and flat strands such as:

Flexible busbars offer greater freedom of movement and are easier to install than fixed busbars. They can also be better adapted to the environment and require less installation space. In addition, they are often lighter and less expensive than solid busbars.

There are certainly flexible busbars that are suitable for high currents. However, it is important that the busbars meet the requirements of the electrical installation and that the maximum current is not exceeded. We will be happy to advise you.

Flexible busbars customized

Whether you need flexible busbars made of highly conductive Cu-ETP1 copper braiding or laminated components, we manufacture everything from simple components to fully pre-assembled assemblies, tailored to individual customer requirements.

We engineer flexible busbars

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

EMS Core Competencies

All from a single source

Reliability, quality, and sustainability are our standards. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFor experts by experts

Our experienced EMS designers ensure that the results meet your requirements, from analysis to prototype production.

We have more than two decades of technical expertise in the field of high current technology and can find a system solution for almost any application!

Do you have any questions about our engineering?