When space and performance matter

In modern battery systems, whether in electric cars, industrial storage facilities or high-performance drones, every detail counts. Traditional cable connections are often too bulky, too heavy or cause excessive losses. The answer to these challenges is our laminated busbar technology.

We manufacture customized laminated busbars from thin, highly conductive sheets with individual contours and reliable insulation. The result is higher efficiency, longer service life and improved safety for your battery systems.

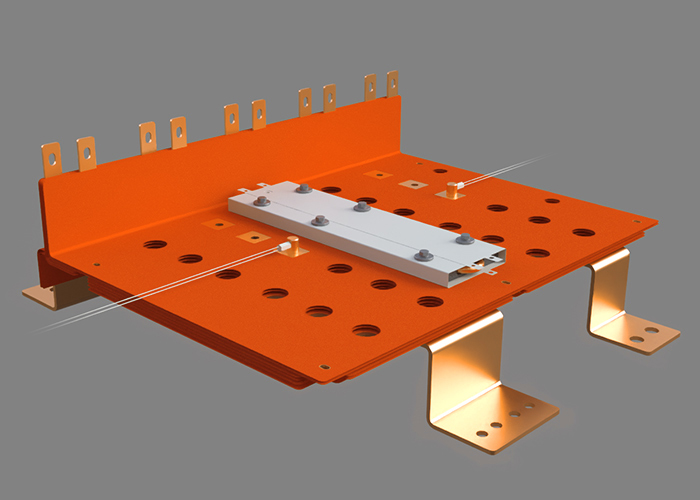

Laminated Busbars as a multifunctional system platform

Individual components or assemblies

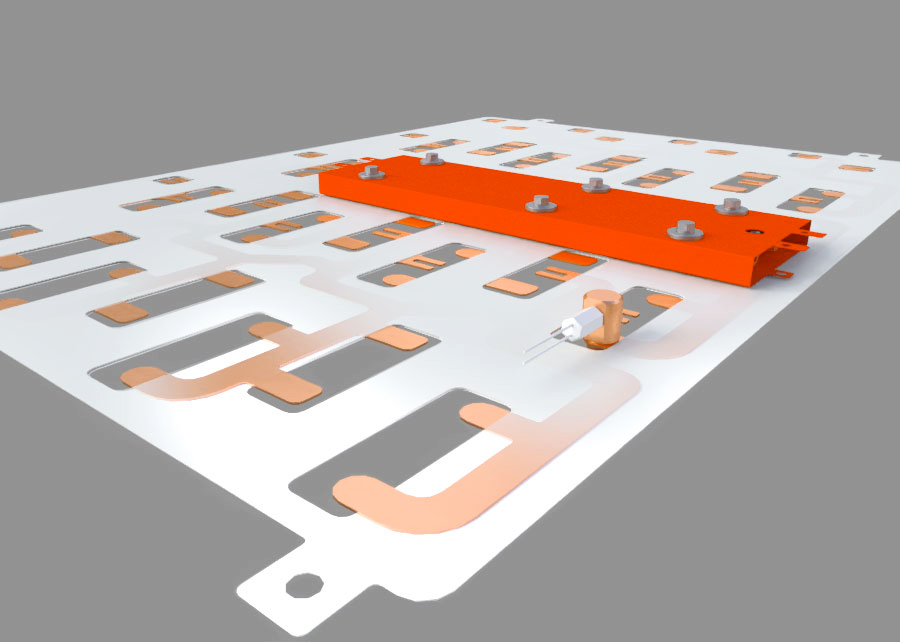

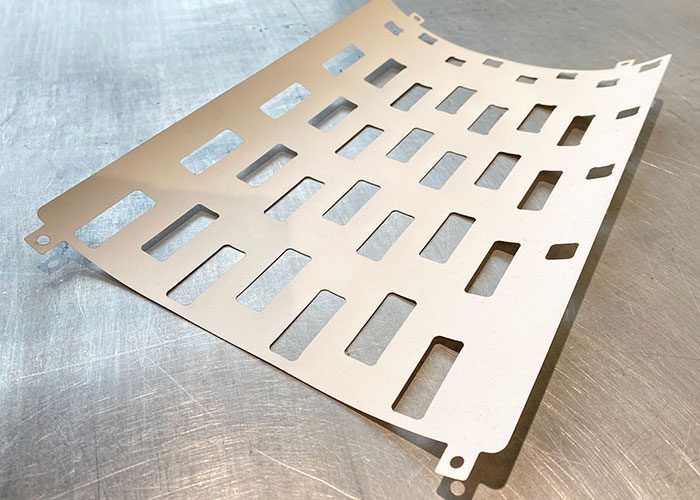

Laminated busbars essentially consist of a multi-layer sandwich structure made of conductive copper, aluminium or cupal sheets, which are separated from each other by thin but strong insulating materials (dielectrics).

In accordance with the classic sandwich principle, these can be supplemented with additional layers at any time, allowing cross-sections and insulation to be individually adapted. This design also allows the electrical conductors to be positioned extremely close to one another. This optimizes electrical performance while creating a compact, robust design.

Entire assemblies can also be manufactured using this modular method.

Additional sensors

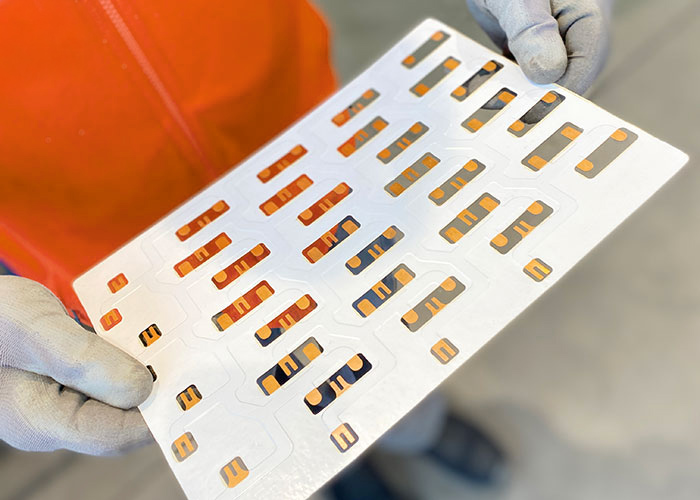

Intelligent monitoring: In the field of drone battery packs, temperature sensors and stack connectors are required, among other things, to efficiently connect the next battery layers. We can precisely meet this requirement with our technology.

Sensors and stack connection: Integrated mounting points for sensors or other attachments are located directly on the busbars.

Attachment of cooling elements: For high-performance applications, a cooling unit can be attached directly to the busbar if required. This supports efficient thermal management and prevents overheating.

Process reliability through controlled lamination

Our technical specifications ensure reproducible and highly reliable insulation of laminated busbars. They are based on precisely controlled lamination processes and process parameters that are based on extensive testing. These correspond to the current and recommended values. This ensures the ideal adhesive bond.

The maximum pressing temperature and sufficient pressing time are crucial for adhesion. These must not be exceeded. In addition, uniform specific pressure must be applied across the entire surface. Furthermore, a special adhesive must be used that adheres reliably to all standard copper grades, with or without tin plating.

From electric cars to drones

Flight systems such as drones: In this lightweight construction segment, every gram counts. Our sheet metal busbars are therefore lightweight and have a high power density for maximum flight time and performance.

Electromobility such as commercial vehicles: Our customized and flexible connection systems enable hundreds of cells to be connected in modules and packs with a vibration-resistant and permanently low-resistance connection.

Stationary energy storage systems such as battery containers: Laminated busbars ensure optimum power distribution at very high currents in large battery storage containers for grid stabilization.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationMaximum performance through optimisation

Low resistance

The use of highly conductive, thin sheets and precise solder connections significantly reduces electrical resistance compared to cables or thick rails. This minimises ohmic losses, reduces heat generation and increases the overall efficiency of your battery system.

Minimum inductance

The laminated construction creates internal self-compensation of the magnetic fields. This results in drastically minimised parasitic inductance. There are fewer voltage spikes (transients) when switching high currents quickly. This is crucial for protecting sensitive power electronics such as inverters and converters.

Improved thermal management

The large, flat surface area of the thin sheet metal, combined with its compact integration into the cell module design, improves heat dissipation from the cells and connection points.

This allows the system to operate at a lower temperature, which slows down the ageing process of the battery cells and significantly extends the service life of the entire battery system.

Customized solutions for electrical connections

If you are looking for a connection solution that combines performance, space savings and the integration of important system functions with maximum process reliability, our customised laminated busbars are the perfect choice. We adapt precisely to your requirements:

Udo Müller

Sales Manager

P +49 6307 9116 981

M +49 152 283 172 49 5

E umueller@ems-power.com