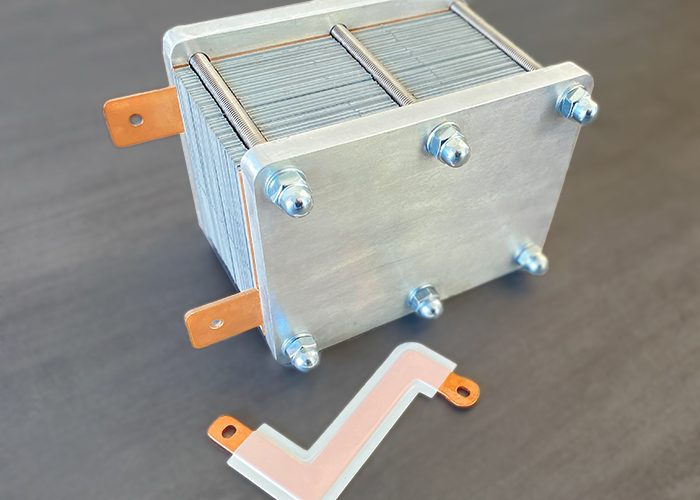

Multi-layer power distribution

Reliable power distribution is crucial in the fields of power electronics and energy technology. Conventional cable systems often reach their limits here. Modern high-performance applications are increasingly turning to laminated busbars as a solution.

These precisely laser-cut sheet metal components are much more than just thick wires. They represent a technological revolution and ensure that systems become more compact, reliable, and electrically efficient.

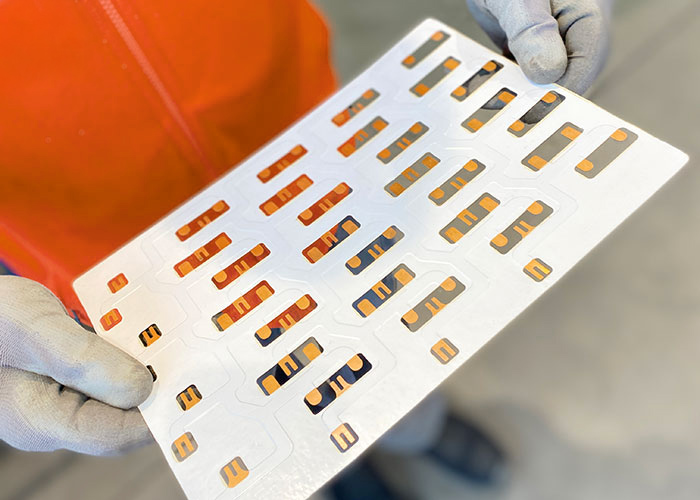

Ultra-thin sheets & foil busbars

Manufacturing using the sandwich principle

Laminated busbars are essentially a multi-layer sandwich structure consisting of conductive layers separated by thin but strong insulating materials (dielectrics). We use copper (CU-ETP), aluminum, or cupal sheets as the conductor material.

All materials can be tin-plated or nickel-plated as required and depending on the application. Extremely thin, high-quality, and durable films made of materials such as PET, PEN, PI, NOMEX, or MYLAR A are used as dielectrics, i.e., as insulation materials. The layers are bonded together under high pressure and high temperature through lamination to form a strong, robust unit.

Electrical feature

This design’s main advantage lies in its electrical properties. Due to the arrangement of the conductors, the magnetic fields of the currents largely cancel each other out. The plus and minus conductors are directly above each other and are separated only by a thin layer of insulation.

This minimises inductance (L), which is important for fast-switching power semiconductors, such as IGBTs or SiC MOSFETs. The two closely spaced conductor tracks form a large plate capacitor. This capacitance acts as a smoothing buffer, suppressing transient voltage changes.

Applications for laminated busbars

Thanks to their superior performance and reliability, laminated busbars have become the standard in numerous high-tech areas.

Electromobility: They form the heart of power distribution in battery packs and drive inverters for electric and hybrid vehicles. They enable the safe transmission of high currents between the battery, motor control, and charging components.

Renewable energies: Laminated busbars are installed in the power converters of solar inverters and wind turbines. These convert the energy generated and thus ensure low-loss and interference-free power distribution in these high-performance systems.

Other areas of application

Industrial drives and control systems: Laminated busbars are used in frequency converters and other demanding industrial power converters that require precise control and low electrical interference.

UPS systems and data centers: Laminated busbars offer a robust and compact solution for power distribution in these applications. They are particularly suitable for uninterruptible power supplies (UPS) and data centers, where reliability is paramount.

Advantages of laminated busbars

With the help of our laser punching machine, we process sheet metal formats for laminated busbars automatically and with precise contours. With our punching tools, pull-throughs, roll beading, offsets, and markings can be realized in no time at all. Our development and production teams always have the right solution at hand, no matter how individual your requirements are.

Reduce voltage overshoots (dV/dt), thereby improving the efficiency of the entire system.

Prevent short circuits between potentials.

Reduce electromagnetic interference (EMI).

Lower the operating temperature of the connected semiconductors, thereby extending the service life of the system.

Thus improving electromagnetic compatibility (EMC).

Increase operational safety thanks to outstanding mechanical strength and resistance to vibrations.

Improve heat dissipation thanks to a large, flat surface.

Increase the potential complexity.

Avoid wiring errors, as the prefabricated component is supplied with fixed connection points.

Increase the packing density and thus enable a smaller overall volume, which is particularly advantageous in electric vehicles.

Enable higher switching frequencies and thus more compact designs.

Reduce assembly time.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAre you looking for powerful alternatives to conventional cable clutter?

Our laminated busbars are key components for the next generation of high-performance electronics. They offer an unbeatable combination of electrical efficiency, reliability, and design flexibility. They have become indispensable for engineers working on the development of electric vehicles, modern power supplies, or renewable energy systems, as they are the slim, powerful alternative to conventional cable clutter.

Michael Stein

P +49 6307 9116 699

M +49 151 153 019 60

E mstein@ems-power.com