How electricity is delivered safely

Data centers are the backbone of our digital world. To ensure smooth operation, the power supply must be extremely reliable. The power supply follows a clear and secure path: First, the medium voltage arriving from public grids is stepped down to the 400 V required for IT equipment in special transformer stations. From there, the electricity usually travels via robust busbar systems to the low-voltage main distribution board (LVMDB). Busbars are often preferred over cables here, as they guarantee particularly reliable and interference-free distribution. The LVMD itself is the heart of the power supply. It distributes the power specifically to the individual sub-distributions, which reliably supply the servers and IT equipment in the data center with energy.

Uninterruptible power supply

Efficient use of valuable space

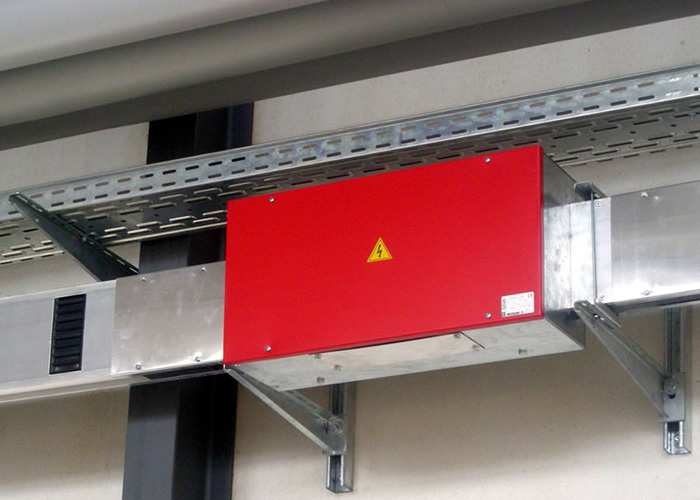

Busbar systems are an ideal alternative to cables, as they are specially designed for high-performance applications. Among other things, they connect the main power supply to transformers or UPS systems.

In addition, busbars are more compact than cable harnesses. This allows valuable space in the data center to be used more efficiently and improves air circulation, which in turn supports cooling. In addition, busbars generally have lower electrical losses than cables, resulting in lower power consumption.

This not only reduces operating costs, but also improves the power usage effectiveness (PUE) of the data center.

Vision®Electric busbar system

Under the Vision®Electric brand, we manufacture innovative busbar systems ranging from 1,200 to 300,000 amps. They are specially designed for harsh and industrial environments and are manufactured precisely to your specifications and requirements, as well as to the relevant IP classes.

The housings of our Vision®Bars (busbar trunks) form the basic framework of the system and are therefore divided into different IP classes.

Vision®Bar - IP Class 31

Use in dry environments and protection against occasional dripping water:

→ Protected against the ingress of solid foreign objects with a diameter greater than 2.5 mm (e.g., fingers).

→ Protected against dripping water falling at an angle of up to 15° to the housing.

Vision®Bar - IP Class 54

Use in dusty environments with simultaneous protection against splashing water, e.g., outdoors in industrial environments:

→ Complete dust protection.

→ Protected against splashing water from all directions.

Vision®Bar - IP Class 55

Use in particularly harsh environments, e.g., in coastal regions or outdoor industrial facilities that must be protected against both dust and powerful water jets:

→ Complete protection against dust.

→ Protection against water jets from all directions.

How to ensure uninterrupted supply

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationIn the digital world, server farms, data centers, and IT rooms are the beating heart of the infrastructure. To ensure their smooth operation, maximum security, availability, and cost-effectiveness of the power supply are an absolute must. Even a short power outage can lead to massive data loss and immense costs.

An uninterruptible power supply (UPS) serves as a lifeline in an emergency. In combination with robust busbar systems, a reliable power supply to the server racks is ensured. These busbars offer significant advantages over conventional cables – especially in terms of scalability and flexibility.

One key advantage is their easy expandability. As the need for servers or racks grows, additional connections (known as tap-offs) or modules can be added without any problems and without the need for costly rewiring of the entire infrastructure. Although the initial costs for busbars are generally higher than for conventional cables, the investment pays for itself in the long term. Simplified maintenance and uncomplicated expansion options make busbar systems an economically attractive solution.

When planning a future-proof infrastructure, it is therefore essential to calculate not only current but also future power requirements precisely and to plan for corresponding power reserves for future growth.

Secure power supply thanks to busbar systems

Reduction of fire load

Our certified Busbar Systems Vision®Bar significantly reduce the fire load compared to cable installations, resulting in greater safety and convenience. A Busbar System consists of various components that work together seamlessly to ensure reliable power distribution. With our systems, you can easily expand your data center and adapt it to new requirements. They offer a modular and scalable solution that can keep pace with the growing demands of a data center.

Consumer locations can be easily relocated by moving tap off boxes without having to rewire the entire system. This not only simplifies installation considerably, but also makes changes and maintenance easier, as these can often be carried out without interrupting the power supply.

Vision®Rail

Tap-off boxes such as Vision®Rail are important interfaces for connecting individual consumers such as server racks to the busbar. They usually contain circuit breakers and fuses.

Retrofit

In this context, the term “retrofit” is also relevant, which refers to the subsequent modernization or adaptation of existing systems. The main objectives of a retrofit are to increase efficiency, reliability, and functionality, as well as to ensure compliance with current standards and regulations. The renewal of busbar systems as part of such a process requires careful planning and execution to ensure efficient and safe modernization.

Are you planning a data center?

Switching to busbar systems is a strategic investment in the future of any data center. They improve the efficiency and reliability of the power supply and make the infrastructure more future-proof and flexible. I would be happy to advise you:

Michael Stein

P +49 6307 9116 699

M +49 151 153 019 60

E mstein@ems-power.com