Compact, powerful, and future-proof

Electromobility is developing rapidly, vehicles are becoming more powerful, charging times shorter and ranges longer. This also increases the demands on the components used, especially in the area of energy transmission. Modern busbars play a central role in electromobility – inconspicuous but highly effective components that allow electricity to flow safely.

High performance in a small space

Electrical power distribution

Busbars are the backbone of electrical power distribution, whether in electric vehicles, fast charging stations, or battery storage systems. Their task: to safely transmit high currents with minimal voltage drop, without excessive heat generation and with low space requirements.

Compared to conventional cables, busbars, especially flat or flexible versions, offer clear advantages: better heat dissipation, lower inductance, higher current carrying capacity, and simplified installation. This is crucial for efficiency and reliability, especially in the power electronics of modern electric vehicles.

Focus on technical requirements

Current carrying capacity (I): Depends on the cross-section, material, temperature, and continuous current load. A typical copper bar measuring 10×3 mm can carry around 150–200 A continuously – and even more with forced cooling.

Inductance (L): The flatter and wider the busbar, the lower the inductance – ideal for power electronic systems with fast switching operations.

EMC behavior: Good busbar routing can minimize electromagnetic interference (EMI), especially through parallel connection of forward and return conductors or shielding concepts.

Insulation: High-quality insulation protects against short circuits and allows space-saving installation of multiple conductors in a single package.

Flat designs

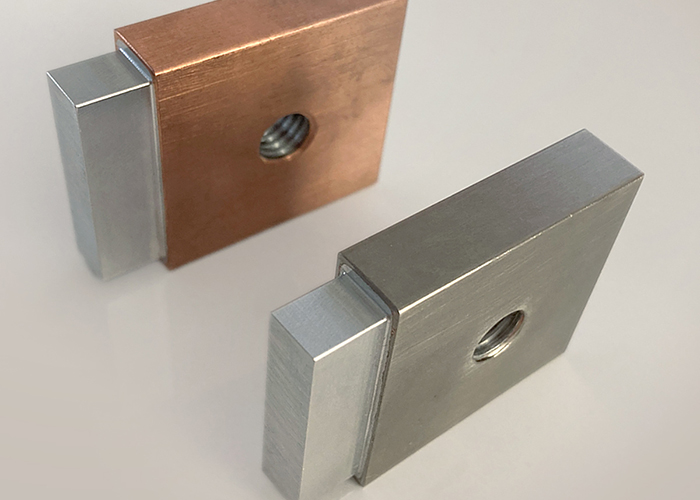

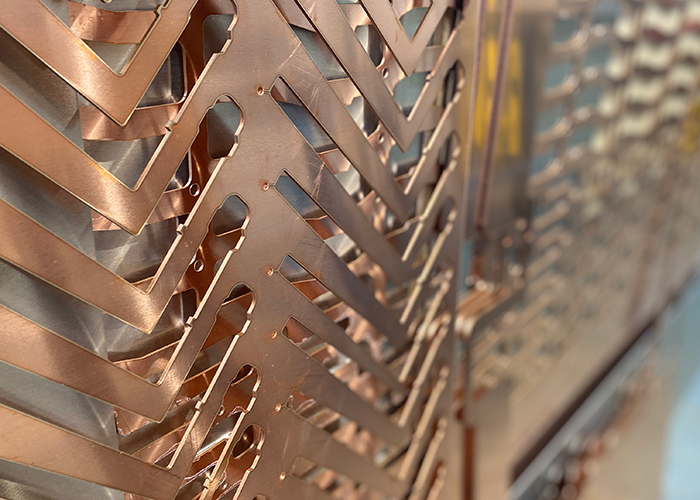

Flat busbars made of copper, aluminum, or cupal sheets connect the power electronic components to each other and to the battery, or transfer energy from the inverter to the electric motor. Their flat design makes them particularly suitable for space-optimized designs.

The large surface area of the busbars can also be used for passive cooling. Their individual geometry allows the motor connections to be designed individually and thermally optimized. They also reduce inductance, which is crucial for fast switching operations in power electronics. In addition, sensors such as temperature, current, or voltage sensors can be integrated into the sheets by laser welding or press-fitting.

Flexible busbars for demanding installation spaces

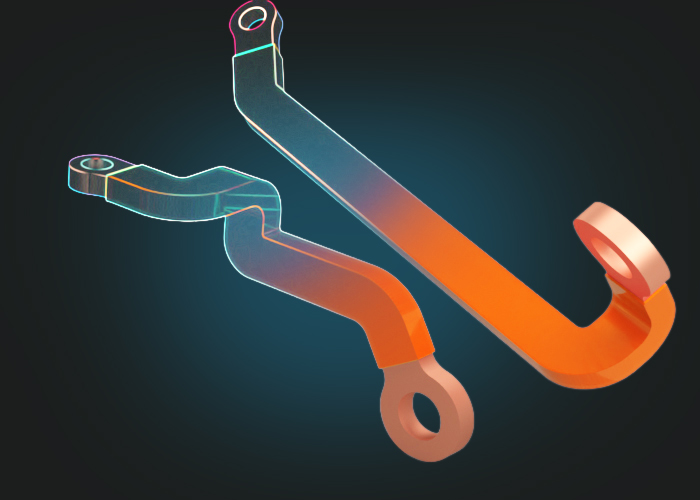

In addition to rigid busbars, flexible busbar solutions are increasingly being used. These usually consist of copper lamellas or copper braiding, enabling three-dimensional installation – ideal for limited installation spaces, such as those found in modern vehicle architectures or fast charging systems.

Power connectors are innovative busbars that, thanks to their design and choice of materials, can transmit more power than usual in a smaller space. These busbars can be easily and modularly integrated into an existing system using plug connectors.

Fault-free & safety

In electric mobility, heat dissipation plays a crucial role in preventing overheating and the associated damage. Solutions such as integrated heat sinks and optimized insulation enable efficient heat dissipation. However, compact busbars are becoming increasingly important not only in electric cars, but also in railway technology, industrial automation, and storage environments (e.g., battery cabinets, container solutions). In rail vehicles, for example, large aluminum structures such as car bodies, roof systems, or container superstructures must be grounded. Grounding lugs ensure that the operating current is returned to the ground in accordance with standards and reduce interference. Grounding lugs can be used as connections for grounding cables.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Our EMS employees make the decisive difference and are the expertise behind our company.

We take all our customers seriously and want to meet their individual needs in the best possible way.

Our experienced designers can find the right solution for almost any application. Thanks to state-of-the-art software and technical expertise, we can simulate various electromagnetic, mechanical, and fluid dynamic phenomena in a single model.

We are a certified welding company in accordance with DIN EN ISO 3834 T3. Our experienced manufacturing team works in multiple shifts to ensure that we can respond flexibly and manufacture your components and assemblies in the required quality.

The EMS Group’s quality management system is certified according to DIN EN ISO 9001:2015.

With CE and UL certification, we also give top priority to environmental protection and safety.

Are you planning a new project?

Engineering compact and highly integrated busbars is key to meeting the requirements of modern electric mobility and power electronics in a future-proof manner. Thanks to innovative materials, intelligent designs, and precise manufacturing, energy transmission in vehicles, charging stations, and industrial systems is becoming increasingly efficient.

Our tailor-made busbar solutions offer enormous potential – whether for increasing range, miniaturization or thermal optimization of your application. We would be happy to assist you in selecting and developing the right busbar solution – individually tailored to your requirements.

Together with you, we engineer forward-looking solutions for the mobility of tomorrow. Contact us – we will be happy to advise you.