EMS Power for Electrical Power

- Engineering & Manufacturing

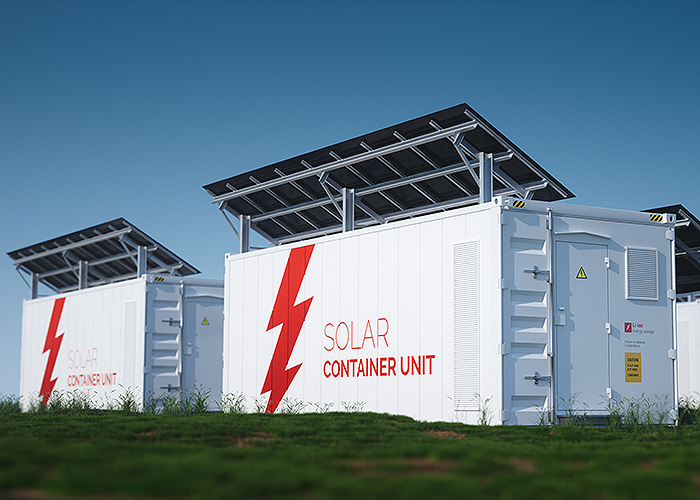

- Energy Storage & Power Supply

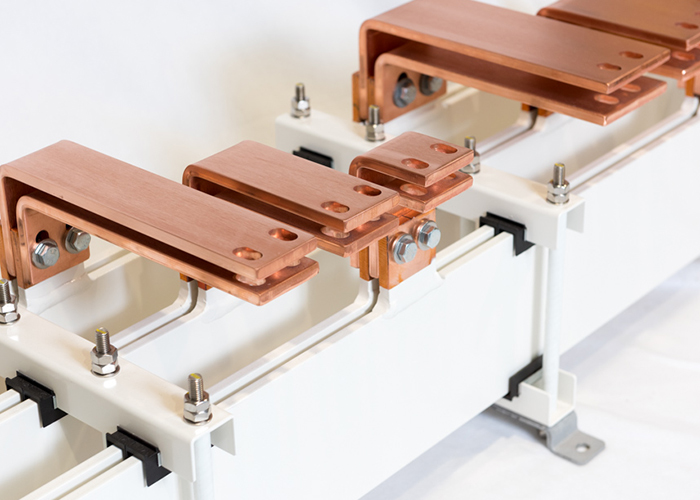

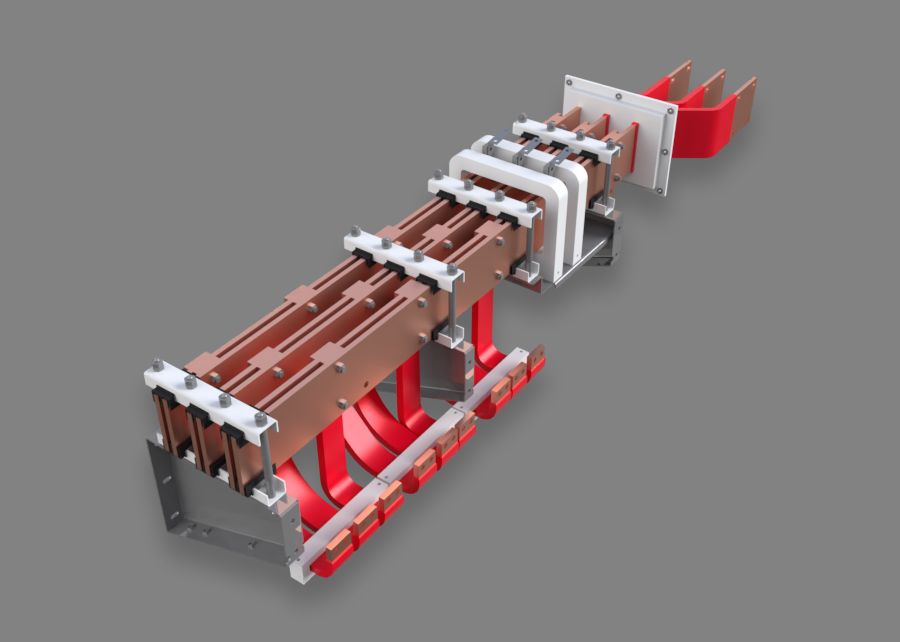

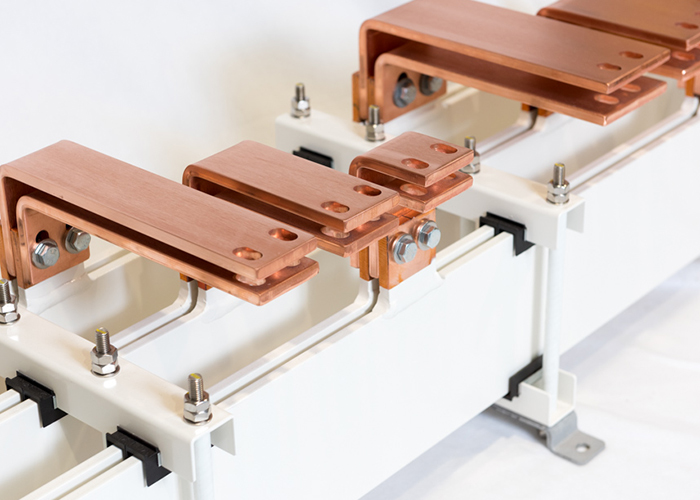

We are your expert for customised High Current Technologies, integrated system solutions, custom manufacturing, individual engineering and assembly of busbar units. In addition to our technically advanced busbar systems, we are able to offer customized support at all stages of the engineering and manufacturing process. Many experts see green hydrogen as the energy source of the future for industry, heat supply and mobility. This process requires a reliable and stable power supply before, during and after the electrolysis of hydrogen. Our busbar solutions are an efficient method of transmitting electrical energy and provide an important, reliable and flexible power supply for all stages of the electrolysis process. Get in touch with us.

Your exhibition contact

Michael Stein

Sales Manager: Basic Industry & Electrolysis

P: +49 6307 9116 699

M: +49 151 153 019 60

E: mstein@ems-power.com

Florian Müller

Sales Manager: Energy Storage & Power Supply

P: +49 6307 9116 178

M: +49 162 203 672 5

E: fmueller@ems-power.com

Your request

Our service

Consulting

+ Individual offer

+ Detailed measurement

+ Guarantees

+ Contract conditions

+ Cost optimization

+ PPAP production release procedure

+ APQP guidelines

+ Audits

Engineering

+ Project management

+ Technical engineering

+ Cross-section design

+ Magnetic field calculation

+ 3D layout creation

+ Feasibility check

Customized manufacturing

+ Fabrication & Manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assemblies

+ Further processing

+ Personalizations

Logistics

+ Worldwide shipping

+ High quality packing

+ Upon request according to specification

+ Reliable & just-in-time

+ Dynamic capacity adjustment

Installation

+ Pre-assembly ex works

+ On-site installation

+ Supervision

After Sales

+ Maintenance

+ Spare parts requirement

+ Retro-fit

For industrial customer requirements

System solutions for electrolysis

- Chlorine, Copper & Hydrogen Electrolysis

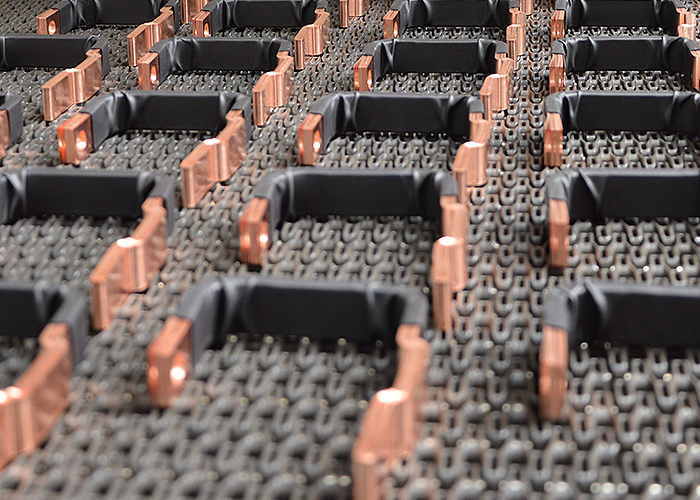

Busbars are mainly used in power distribution, centralized or decentralized power generation and energy-intensive processes such as electrolysis (hydrogen electrolysis). We engineer your environment-adapted and corrosion-resistant high-current connections, always taking into account magnetic fields, pollution levels and chemical compatibility – even or especially for existing infrastructure! With our many years of experience, EMS Elektro Metall Schwanenmühle is your competent partner for electrical busbars in the field of high-current technology – even for very high currents of 10,000–300,000 amperes! For more Information click here.

Busbars for energy grids, storage & supply

- Components for stationary storage

- System solutions for networks & energy supply

For safe power transmission within your equipment, such as transformers, converters or HVDC rectifiers, we develop and manufacture individual busbar system solutions according to your specifications.

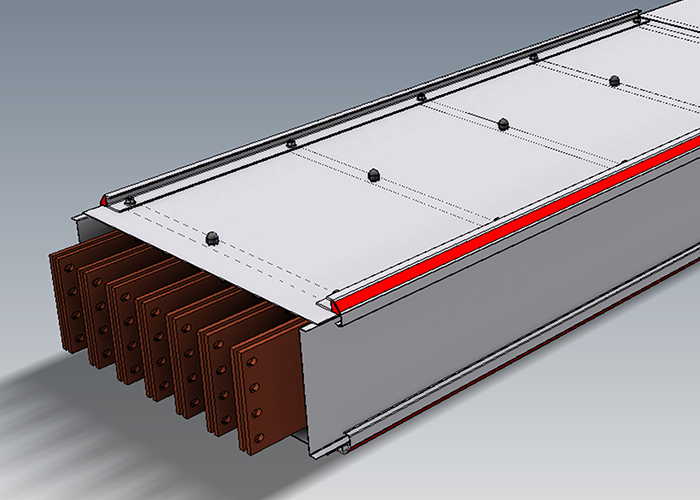

Busbar systems with Vision®Electric

- Vision®Bar

- IndustryBar

- Vision®Rail

Under the Vision®Electric brand, we primarily manufacture innovative busbar systems in the 1200-300,000 ampere range, specifically for harsh and industrial environments in the primary industry according to customer specifications. For more Information click here.

System solutions for your basic materials

EMS stands for holistic services

In close cooperation with you, we engineer projects systematically and implement them efficiently.

The focus is on optimizing functionality as well as on infrastructural, production-related and economic aspects. The result is individual solutions that are geared to cost-effectiveness and meet the customer’s requirements down to the last detail.

EMS Core Competencies

All from one source

Reliability, quality and sustainability are our claim. As a strategic partner, we are the first choice for our customers.

Engineering Busbars

We support you in the technical engineering of system solutions for individual requirements. Feel free to contact us!

Installation

If required, we can also assemble our busbar solutions at your site or take over the pre-assembly of your assembly units, ex works.

Manufacturing

Maximum precision through know-how and modern machines – our manufacturing professionally implements even complex busbars solutions.

Worldwide Shipment & Logistics

We assemble your finished busbar orders into flexible shipment units according to your specifications – customized and on time!