The future starts today, not tomorrow

Busbar systems are a central component of modern energy distribution. They are used in industrial plants, electromobility, data centers, and many other areas. Continuous support from professional after-sales services is essential to ensure that these systems operate efficiently and without disruption over the long term.

We not only offer high-quality busbar systems, but also provide our customers with long-term support in the form of customized services for maintenance, repair, and modernization.

Making existing busbar systems future-proof

The significance of expert assistance

Busbar systems are an investment that only pays off in full if they function reliably over the long term. Professional after-sales services can significantly extend the service life of the system. At the same time, the risk of unplanned outages is minimized, legal testing requirements are met, and energy efficiency can be improved in the long term.

Companies also benefit from better cost control, reliable system availability, and increased sustainability.

Retrofit for busbar systems

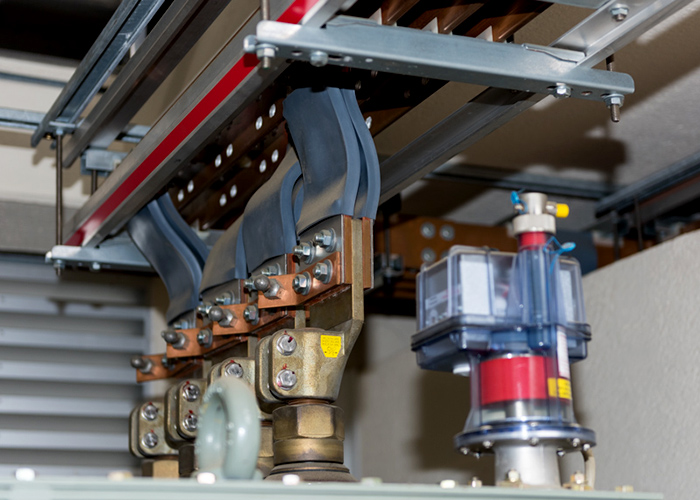

If technical requirements change in a company or older systems no longer meet current standards, a retrofit is the ideal solution. This allows existing busbar systems to be modernized economically and sustainably without the need for a complete replacement investment. We support you in integrating modern protection and measurement technology, for example by retrofitting modular systems. It is also possible to expand existing systems to accommodate additional consumers or adapt them to changed production processes without any problems. In addition, the company ensures that all retrofit measures comply with the applicable safety regulations and technical standards. The use of energy-efficient components also reduces operating costs in the long term while supporting ecological goals. This allows you to modernize your existing infrastructure economically while conserving resources.

Digital twin

The digital twin is a forward-looking component of modern busbar systems. It is a virtual image of the real system and linked to it in real time.

We use the digital twin specifically to make the maintenance, repair, and modernization of busbar systems even more efficient, safer, and more predictive.

The digital recording of all components, operating data, and measured values creates a complete, dynamic image of the system. This digital twin enables the seamless documentation of all service processes and the targeted, location-independent analysis of operating states.

System maintenance

To ensure the long-term operational reliability of a busbar system, regular maintenance is essential. We rely on proven inspection methods and state-of-the-art measurement technology. The scope of services includes a thermographic inspection of the systems. This allows possible heat development or contact resistances to be detected at an early stage. In addition, all connection points, brackets, and feed points are checked as part of a visual and functional inspection to identify mechanical or electrical defects in good time. Electrical measurements such as determining the insulation resistance are also part of the maintenance. In addition, the busbars are thoroughly cleaned to prevent corrosion or deposits that could impair their function.

Maintenance in case of malfunctions

A busbar system is an investment that only pays off in full if it functions reliably over the long term. Professional after-sales services can significantly extend the service life of the system. At the same time, the risk of unplanned outages is minimized, legal testing requirements are met, and energy efficiency can be improved in the long term.

In addition, companies benefit from better cost control, reliable system availability, and increased sustainability.

EMS

Services

Consulting

+ Individual offer

+ Detailed measurement

+ Warranties

+ Contract conditions

+ Cost optimization

+ PPAP Production Part Approval Process

+ APQP Guidelines

+ Audits

Engineering

+ Project management

+ Technical development

+ Design of cross-sections

+ Magnetic field calculation

+ Design & drawing

+ Feasibility check

Custom Manufacturing

+ Assembly & manufacturing

+ Highly flexible busbars

+ Flexible busbars

+ Solid busbars

+ Flat busbars

+ Busbar systems

+ Busbar assembly units

+ Further processing

+ Customization

Logistics

+ Worldwide shipping

+ High-quality packaging

+ Tailored to your specifications

+ Reliable and just-in-time

+ Dynamic capacity adjustment

Assembly

+ Project management

+ Pre-assembly ex works

+ Assembly on site

+ Competent assembly teams

After Sales

+ Maintenance

+ Spare parts requirements

+ Retrofit

Are you planning a new old project?

If you are planning maintenance, need short-term support with repairs, or want to upgrade your busbar system to future-proof it, our team is here to help. Together, we will engineer a customized service concept that is precisely tailored to your technical requirements. I would be happy to advise you:

Michael Stein

P +49 6307 9116 699

M +49 151 153 019 60

E mstein@ems-power.com